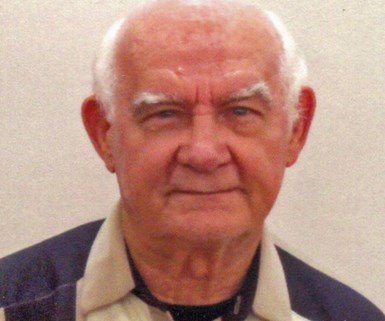

Boser Gets SPE Thermoforming's Lifetime Achievement Award

Long-time thermoformer and author gets top honor at SPE conference.

The Society of Plastics Engineers (SPE) Thermoforming Division has presented its Lifetime Achievement Award to Leroy (Lee) Boser, an expert in thermoforming technology who worked for Spartech and other companies for nearly four decades and authored two well-known thermoforming manuals.

The Division’s Executive Committee presented the award to him on September 10, during SPE’s Thermoforming Awards Dinner at the Hilton Milwaukee City Center Hotel in Milwaukee.

Boser began his career in 1967 as a plant supervisor with Uniroyal. After 11 years, he left to become general manager at Riblet Plastics, where he worked for six years until returning to Uniroyal in 1985. Fifteen years later, Uniroyal’s sheet business was acquired by Spartech Corp., and Boser became the chief sales engineer until he retired in 2005. He now serves as a thermoforming engineer consultant to many of Spartech’s customers.

Throughout his career, Boser has traveled around the world to help set up thermoforming operations and troubleshoot customer challenges in the U.S., Canada, England, Scotland, Germany, Romania, Australia, and China.

Boser played an instrumental role in the introduction of Spartech’s Royalite and Royalex materials. Royalite sheet is an engineered thermoplastic alloy designed for aviation, mass transit, medical and building and construction applications and meets stringent flame and smoke requirements. Royalex contains a post-foaming technology which was used extensively in the manufacture of high-end canoes.

Boser has published two notable thermoforming manuals: Pressure Forming Manual in the early 1990s and Thermoforming Manual and Troubleshooting Guide a decade later.

Boser holds a Bachelor of Science Degree from the University of Illinois. A longtime member of SPE, he joined the Board of Directors of Rotational Molders in 1980, and served on their board for five years.

“I had the privilege of seeing Lee Boser in action during my resin-selling days, and I was always amazed at how he could show a customer how to troubleshoot an issue (which quite often was not a material issue), and do it in a way where the customer was grateful,” said Eric Short, SPE Thermoforming Division Chair. “While processors are the core of our industry, there is an often unsung supporting cast of resin producers, sheet extruders, tool makers, and other suppliers who have partnered with the processor to help accomplish great things. Lee Boser’s career epitomizes that partnership.”

Related Content

-

Thermoforming PCR: An Equipment Supplier’s Pointers

Thermoforming PCR is not radically different from forming virgin, but variation in recycled materials can require extra care to get a consistent end result. Start by examining every aspect of the process from the sheet (and extrusion process if run inline) to the final trim.

-

Cobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

-

An Automation 'First' for Non-Servo-Eject Trim Presses

Compact, flexible and configurable robotic system is said to be the first to enable thermoformers to fully automate product handling after a non-servo trim press.