Clariant and Floreon to Collaborate on 'Performance' Biopolymers

A collaboration between Clariant and Floreon aims at expanding high-performance biopolymer applications to more markets.

Clariant’s Additives Business (U.S. office in Charlotte, N.C.) and the U.K.’s Floreon Transforming Packaging Ltd., recently announced a new collaboration to further extend the performance properties and market potential of Floreon’s proprietary PLA compounds, through the use of Clariant’s broad portfolio of sustainable additives, including a wide range of high-performance biobased addititives.. Markets set to benefit from the new enhanced grades include rigid and flexible packaging, electrical & electronic equipment, healthcare products, consumer goods and automotive.

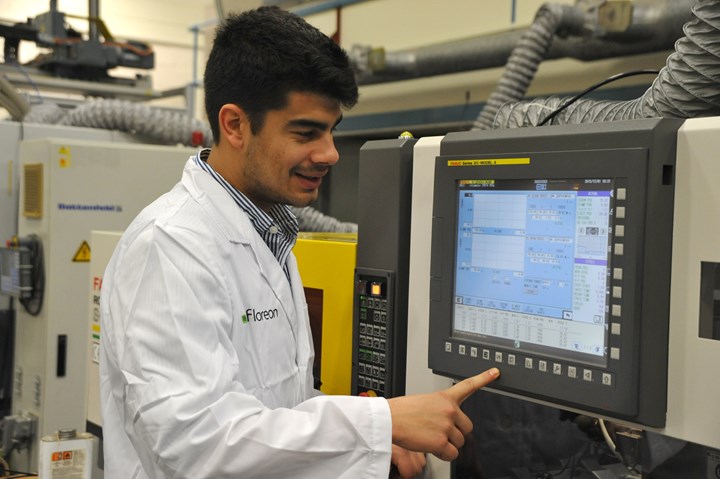

Floreon develops and markets proprietary PLA-based compounds containing 70-90% renewable, plant-based raw materials. They are said to be mechanically tougher than traditional PLA and can deliver significant energy savings in processing. Floreon compounds are recyclable and they can also be composted via industrial composting. That makes Floreon’s materials viable for applications where, at this stage, contamination with food waste and organic matter make mechanical recycling unfeasible.

Clariant’s biobased additives were launched at K 2019 Plastics Trade Fair under the Exolit OP Terra, Licocene Terra and Licocare RBW Vita trade names. This is the result of the company’s partnership with with Finland’s renewable hydrocarbon producer Neste/ These renewable hydrocarbons are based on sustainably-produced biobased raw materials, such as waste and residue oils.

The Exolit OP Terra renewable-based halogen-free flame retardants are said to deliver the well-known performance and sustainability advantages of the company’s fossil-based Exolit OP flame retardants for applications such as electronic and electrical equipment and automotive components. They achieve UL 94 V-0 rating with stable flame retardancy even after multiple recycling processes.

Licocene Terra is a renewable feedstock version of Clariant’s famous Licocene range of lubricants including both waxes for plastic processing—particularly for polyolefins, PVC extrusion, EPS, and as a dispersing agent for pigments and additives--and performance polymers as hot melt adhesives that allow bonding and debonding and improve the recyclability of post-industrial and post-consumer waste

In addition to its Terra range, Clariant launched Licocare RBW Vita range of rice bran wax based solutions for formulators of high-performing engineering plastics, bioplastic compounds and masterbatches. Based on non-food competing feedstock, these are the first products to carry Clariant’s Vita designator for products from natural origin with at least 98% RCI, Renewable Carbon Index, renewable content. Included is a multifunctional additive that provides a special combination of lubrication and nucleation in engineering plastics, particularly in nylons.

Clariant’s experts will support the Floreon development team to enhance the performance possibilities and processing characteristics of bioplastics.The scope of benefits is vast. Examples include achieving less energy use and faster cycle times by increasing the processing efficiency or adding completely new properties to the material. Product manufacturers will have the possibility to tailor compounds to suit specific processing technologies and applications, including in some cases those where bioplastics have so far not been able to meet the challenges of demanding conditions or environments.

Stephan Lynen, Clariant’s head of the additives business unit said, “We are excited to be working together with Floreon using the advantages of our range of sustainable additives to close the performance gap between biopolymers and other materials. This is just another way we can contribute to giving the plastics value chain a greater choice of options for meeting sustainability targets and consumer demands, and in doing so, support the transformation to a circular economy. For society, our environment, and future generations, it is our responsibility to continuously improve sustainability performance and reduce carbon footprint and waste.”

Related Content

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

Read More3 Types of 3D Printed Tooling for Injection Molding

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Read MorePFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreRead Next

New Player in Enhanced PLA Compounds, Additives

Floreon of the U.K. offers -impact-modified PLA that's more than 90% biobased, as well as additive masterbatches.

Read MoreFloreon Has New Investors for "Performance" Bioplastic; Aims to Hit U.S. Soon

Floreon Transforming Packaging of Hull, U.K., has secured multiple new investors through an Enterprise Investment Scheme (EIS) to bring its patent-pending “performance” bioplastic material to market, and the U.S. is its prime regional target.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More