Coronavirus Pandemic Boosts Topas COC Demand

Polyplastics’ Topas COC is already being used in testing kits for COVID-19 and developments in therapy delivery containers are underway.

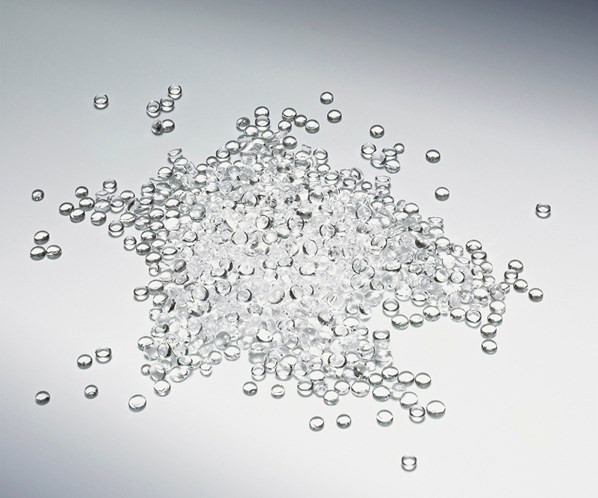

Topas cyclic olefin colpolymer (COC), part of the arsenal of engineering thermoplastic resins offered by Polyplastics USA, Farmington Hills, Mich., has long been used for medical bottles and syringes, a market which has been dominated by borosilicate glass, as well as disposable diagnostic containers. But, there has been a surge of interest in Topas COC as a result of the coronavirus pandemic, TOPAS Americas president Timothy Kneale recently told PT.

Said Kneale, “With a range of new tests and therapies under development, many companies find it important to use the purest, most inert products for their developments. The extremely low leachables and extractables of Topas COC, along with its non-polar, low-reactivity surface and broad global regulatory compliance make it ideal for diagnostic disposables, and for packaging of vaccines and therapeutic agents.” Kneale confirms that while non-disclosure agreements prevent his company from discussing specific programs, COC is being used in Covid-19 testing applications and there are developments underway for its use in new therapies.

Asked if COC could serve to alleviate a current shortage of borosilicate glass used to make vaccine vials, Kneale expects that it can, with some further clarification. He notes that while inexpensive borosilicate glass is a good material, there are emerging drugs and therapies that are incompatible with glass. “This becomes especially more pronounced as the industry moves more into biotech types of drugs.”

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

The Effects of Stress on Polymers

Previously we have discussed the effects of temperature and time on the long-term behavior of polymers. Now let's take a look at stress.

-

New Entrant Heartland Polymers Stepping up as Reliable Supplier

Heartland Polymers’ new Alberta, Canada facility will produce 525 KTA propylene and 525 KTA polypropylene. It is expected to stabilize supply chains across the continent.