Engel to Showcase Sustainability at K 2022

At the world’s premier plastics fair, Engel will emphasize sustainable processing assisted by digitalization.

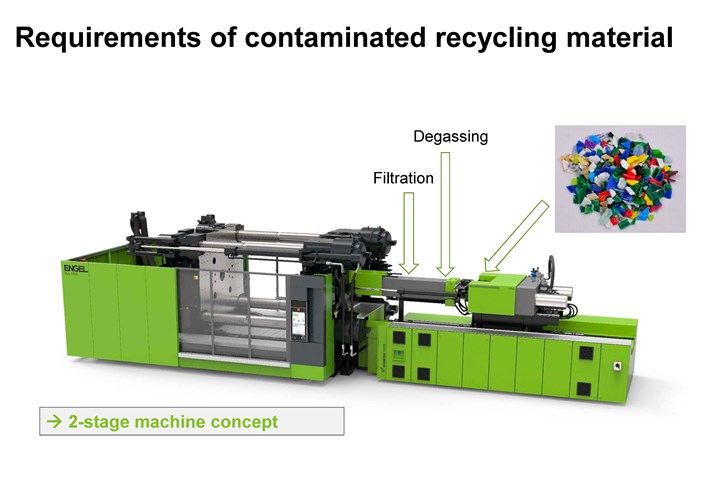

At K 2022, Engel will highlight its new concept for processing recycled flake directly after grinding, using a two-stage injection unit with filtration on the screw plasticating stage and degassing on the injection plunger. (Image: Engel)

At its June press preview of its exhibits at the upcoming K 2022 fair in Dusseldorf this October, Engel put primary emphasis on sustainability, circular economy and reducing carbon footprint. For example, the company highlighted its innovations in mold-temperature control. “Many processors think that they have already achieved the maximum energy savings potential by using an all-electric injection molding machine,” said Dr. Gerhard Dimmler, chief technology officer of the Engel Group. “But a precisely tuned temperature-control solution helps them do far more.”

One tool for achieving that goal is Engel’s iQ flow control, part of its family of “smart assistance systems.” Engel says such software for the “self-optimizing injection machine” is essential for saving energy and material waste by avoiding rejects and tuning the process for maximum efficiency. At the show, Engel will showcase a brand-new addition, iQ hold control.

‘Stretch, Cover & Hide’

For the circular economy, injection molders have three main strategies, which Engel summarizes as “Stretch, cover and hide.” The first of these—“stretch”—refers to mixing recycled with virgin material, which requires the proper injection unit design (Engel is introducing a two-stage concept with filtration and degassing) and self-optimizing control software, such as Engel’s iQ series. “Cover” means using in-mold decorating (IMD) to provide an aesthetic surface for recycled materials. Engel provides foilmelt and clearmelt technologies for this purpose. And “hide” means embedding the recycled content in the core of a sandwich structure with virgin skins—such as with Engel’s skinmelt and coinjection technologies.

Digital Watermarks

In addition, Engel recently joined the R-Cycle consortium of companies seeking to enhance plastics recycling through incorporating “digital watermarks” that are nearly invisible to the human eye, but which can be electronically scanned to convey all the necessary information about the material content, manufacturer and manufacturing process. Digital watermarks can be spread over the surface of a part via in-mold labeling (IML) or embedding within a mold surface texture.

Engel joined R-Cycle in May, shortly after the plastics recycling equipment company Sikoplast also became a member. Based in Germany and founded in 2020, R-Cycle currently has 15 members, including Arburg, Reifenhäuser, Kautex, Erema, Kampf, Brückner Maschinenbau, Multivac and the Institute for Plastics Processing (IKV) in Aachen.

Related Content

-

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

-

Advanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

-

Looking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

.png;maxWidth=300;quality=90)