Enhanced Clamp & Injection Specs Promote New Models from Absolute Haitian

Four new injection machine lines demonstrate commitment to deliver good machine value while responding to customer demands.

Ningbo Haitian Machinery Co. in China is the world’s largest injection machinery supplier—29,500 machines, give or take, delivered in 2016. The economies of scale of such an operation, plus a philosophy of using widely available standard components, account for two advantages, according to Glenn Frohring, president of Absolute Haitian, exclusive representative for Haitian in the U.S. and Canada.

One advantage is economical pricing for new machines and relatively low cost of ownership when it comes to replacement parts. The second advantage, says Frohring, who has more than 32 years of experience in the injection machinery business: “They have a very fast R&D cycle and can bring out new models faster than other suppliers.” That prolific quality is evident at NPE, where Absolute Haitian will show off four new machines, two of them still at the preview stage.

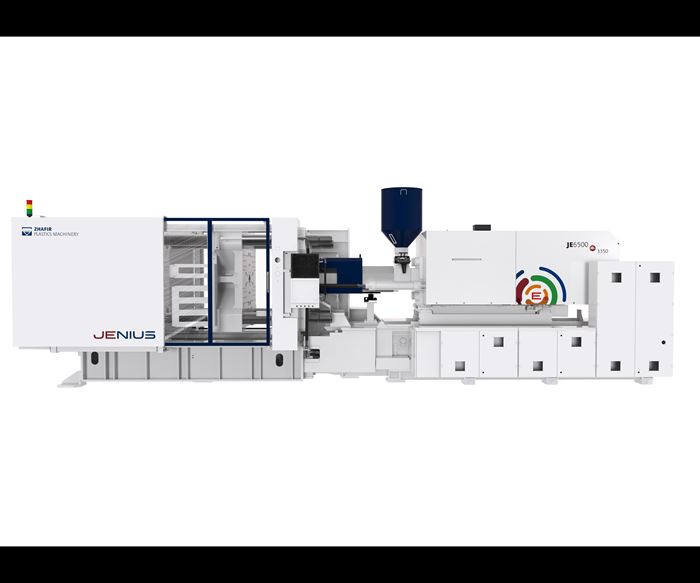

In Frohring’s view, the highlight of the company’s booth (W143) is the new Zhafir Jenius Series, shown for the first time in the Americas to molders looking for energy-efficient precision molding of mid-to-large parts. “We have a lot of automotive customers,” says Frohring, “who like the shorter footprint of two-platen machines. And they run a lot of complex tooling with valve gates, cores and slides that rely on hydraulics.” The Jenius (JE) Series combines the servo-hydraulic two-platen clamp of Haitian’s Jupiter Series with an all-electric injection unit for increased precision and repeatability. That repeatability is pegged by Haitian at less than 0.1 percent variation in part weight from cycle to cycle. “And the electric screw drive allows for screw recovery during clamp movements to save cycle time.”

Other new machines on display show Haitian’s responsiveness to customers’ requests for wider tiebar spacing to handle molds bristling with cores and slides, as well as enhanced injection pressures and faster cycles. One example is the new fast-cycling “2S” version of the Zeres electric series with integrated hydraulics for auxiliary functions (core pulls, ejectors, nozzle touch). Its clamp and injection unit have been redesigned for jobs with cycle times down to 4 sec.

Previews of machines still in development include the third generations of both the Haitian Mars and Zhafir Venus Series. The servo-hydraulic Mars MAIII has generous tiebar spacing that allows a mold that would ordinarily require a 300-ton press to run in a 192-tonner at the show. And the all-electric Venus III Series boasts greater injection-pressure capacity and “the industry’s most generous tiebar spacing,” according to Frohring.

“We build machines to satisfy 85-90% of injection molders, rather than for niche applications,” he adds. “Not everybody knows our machines, but we have sold over 3000 of them in the U.S. and Canada over the past 11 years.”

Related Content

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

Know Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

.png;maxWidth=300;quality=90)