Extrusion: Why There Are No Truly Universal Dies

Flow characteristics of different polymers vary considerably. So while adjustment features are available, for the most part dies must be designed for an individual polymer.

Any given extrusion die can produce a specific shape with only a relatively narrow range of polymers. That’s because polymers are non-Newtonian in behavior; they have different viscosity-thinning characteristics at increasing shear rates.

Shear sensitivity is largely related to molecular weight and molecular-weight distribution, which vary widely between different polymers as well as between grades within the same polymer family. To compensate, many dies have built-in adjustable features to compensate for the flow variations caused by shear thinning in different materials.

To illustrate this point, a sample set of flow calculations for a simple corner molding was made for three different polymers, showing the variation in the profile with each polymer and illustrating the lack of universality.

The larger the die and/or the greater the variation in part thickness, the more that shear thinning affects the flow.

If an LDPE profile with an MI of 2 was extruded at 100 lb/hr (1.03 in.3/sec), it would have a linear velocity of about 22 ft/min. Assuming the original internal geometry of the profile die was properly designed to produce the desired shape with 2 MI LDPE, what would it look like with a 5 MFI PP homopolymer or a 0.76 IV PET?

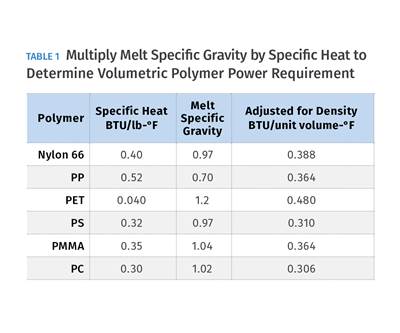

The PP and PET flow rates were adjusted to the same volumetric output to compensate for the differences in density and thus clarify the analysis. If the two “legs” of the profile are treated as separate rectangles for flow analysis, the difference in velocity of the legs between a 2 MI LDPE, a 5 MFI PP and a 0.76 IV PET would produce results like the accompanying illustration.

According to the power-law coefficients, the LDPE and PP have similar shear-thinning tendencies, so even though the viscosity of the 5 MFI PP is about two-thirds that of the 2 MFI LDPE, the flow remains relatively balanced. The vertical leg of the corner profile will have about 18% greater flow rate than the horizontal leg and would distort the part shape.

Know How Extrusion: Get More Insights from Our Expert Authors

It’s the opposite situation for the 0.76 IV PET, which has a viscosity about two-thirds higher than the LDPE. PET’s reduced shear sensitivity creates about 80% greater flow in the horizontal leg, completely unbalancing the profile shape. The differences in flow are caused by the differences in shear rate in the legs, with the vertical leg being half the thickness of the horizontal leg.

At the same linear velocity in both legs, the shear rate is unbalanced because of the difference in thickness between the horizontal and vertical leg. With the shear rate changing exponentially based on the width of the legs, and the viscosity changing logarithmically with the shear rate, it is very difficult to anticipate the flow changes without benefit of rheological data and flow calculations.

The polymers’ power-law coefficients are a reference to the degree polymers change viscosity with shear rate but are too general to be used for computational purposes and vary even within the same polymer type. Working from actual rheological data, this PP shear-thinned more than the LDPE but even more than was indicated by the power-law coefficients. This is likely due to the reduced molecular weight, as represented by the higher MI.

The PET had a very large change in flow between the two legs and was more reflective of the difference in the power-law coefficients, although still well outside what could be used for computational purposes. This analysis shows power-law coefficient values did not reflect the actual differences seen in the die flow for each polymer but are still a general indicator of likely flow variations. Consequently, rheological data is necessary to determine the degree to which polymer shear sensitivity will affect the flow performance of the die.

The sample analysis shows that the flow characteristics of different polymers varies considerably, making die design specialized to an individual polymer. This applies to every kind of die except a round solid profile that is center fed. The larger the die and/or the greater the variation in part thickness, the more the effects of shear thinning affect the flow.

Many dies have adjustable features to give them more range, such as a restrictor bar on a sheet die or an adjustable-pressure ring on a tubular die. Even profile dies can have inserts to give them more range, but something has to be done in every die to compensate for the varying shear-thinning characteristics of polymer types and grades.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

The Importance of Melt & Mold Temperature

Molders should realize how significantly process conditions can influence the final properties of the part.

Read MoreA Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

Read MoreAre Your Sprue or Parts Sticking? Here Are Some Solutions

When a sprue or part sticks, the result of trying to unstick it is often more scratches or undercuts, making the problem worse and the fix more costly. Here’s how to set up a proper procedure for this sticky wicket.

Read MoreHow to Set Barrel Zone Temps in Injection Molding

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

Read MoreRead Next

Extrusion: The Role of Polymer Density in Screw Design

Density affects the mass flow rate, and energy transfer is based on mass, not volume. As a result, polymer density enters into practically every calculation in a screw design.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More.jpg;width=70;height=70;mode=crop)