Flexible, Rugged Systems for Pipe, Profile

High-performance conical twin-screw extruder with calibration basket to change pipe diameter.

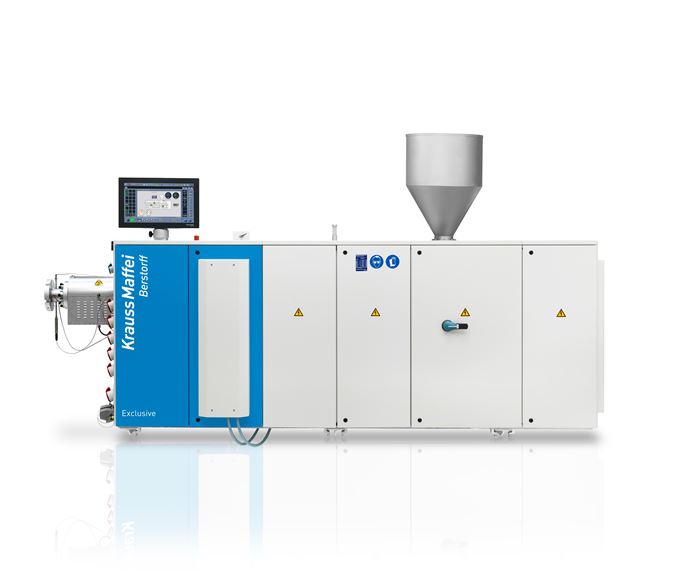

KraussMaffei Berstorff’s booth is highlighted by its flexible, high-performance KMD 73 K/P conical twin-screw extruder and its QuickSwitch calibration basket.

The KMD 73 K/P is said to offer very high output, robust machine quality and high pressure stability. These are properties that processors in window profile production—particularly for mass-produced goods—regard as crucial. The sophisticated process concept makes the series extremely process-reliable and simultaneously very flexible for using various formulations. The optionally available bimetallic barrel liner is paired with a tungsten carbide welded screw—a requirement of the North American market—to permit the machine to be used for pipe extrusion as well. Space-saving and customer-specific designed coextrusion models can also be installed in the smallest of spaces for efficient production.

The machine builder’s QuickSwitch calibration basket allows pipe processors to change the effective diameter range from 11.023 to 19.685 in. (280 to 500 mm). The system is particularly important when changing from larger to smaller dimensions because it minimizes waste during the transition. All process parameters can be set and stored in the higher-level, intelligent all-in-one control system and called up again at any time.

Further downstream, the KM-VT 250/1/6 vacuum tank integrates vacuum control and the frequency-controlled pumps. These, in turn, are fully linked to the C6 line control system for optimum start-up, energy savings and uniform product quality.

Related Content

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Fully Automated Extrusion Process Enables Use of Composites for Manufacturing Pressure Tanks

Amtrol was looking for a more cost-effective means to produce thin-wall liners for a new line of pressure tanks. With the help of a team of suppliers, they built one of the world’s most sophisticated extrusion lines.

-

Updated Software Reduces Die Design Iterations

New software said to reduce the number of fine-tuning iterations and die development time by at least 50%.

.png;maxWidth=300;quality=90)