Lignin-Nylon Composite for Additive Manufacturing

ORNL has created a formulation that could spur a profitable new use of an intractable biorefinery byproduct: lignin.

“Finding new uses for lignin can improve the economics of the entire biorefining process,” said Amit Naskar from the Department of Energy’s Oak Ridge National Laboratory, the project lead of ORNL scientists that have created a recipe for a renewable 3D printing feedstock that could spur a profitable novel use for lignin—the material left over from the processing of biomass. Lignin gives plants rigidity and also makes biomass resistant to being broken down into useful products.

The researchers’ formulation combines a melt-stable hardwood lignin with a low-melting nylon, and carbon fiber to create a composite with reportedly just the right characteristics for extrusion and weld strength between layers during the printing process, as well as excellent mechanical properties. This work tends to be tricky as lignin chars easily. Unlike workhorse composites like ABS, lignin can only be heated to a certain temperature for softening and extrusion from a 3D-printing nozzle. Prolonged exposure to heat dramatically increases its viscosity, making it difficult to extrude.

However, when the ORNL team combined lignin with nylon, they were pleasantly surprised to find that the composite’s room temperature stiffness increased while its melt viscosity decreased. In fact, the lignin-nylon composite demonstrated tensile strength similar to nylon alone and lower viscosity than conventional ABS or HIPS (high-impact polystyrene).

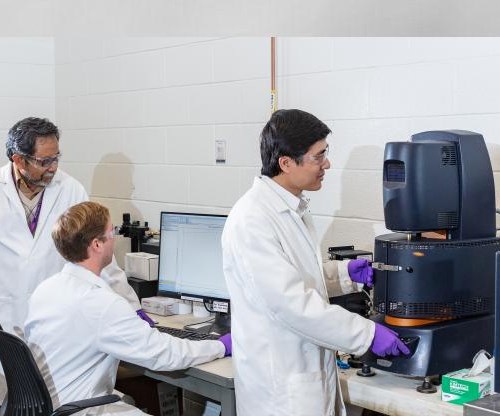

The scientists conducted neutron scattering at the High Flux Isotope Reactor and used advanced microscopy at the Center for Nanophase Materials Science—both DOE Office of Science User Facilities at ORNL—to investigate the composite’s molecular structure. Their key finding: The combination of lignin and nylon “appeared to have almost a lubrication or plasticizing effect on the composite,” according to Naskar. Added collaborator Ngoc Nguyen, “Structural characteristics of lignin are critical to enhance 3D printability of the materials.”

The ORNL scientists were also able to mix in a higher percentage of lignin—40 to 50 percent by weight—said to be a new achievement in the quest for a lignin-based printing material. They then added 4 to 16 percent carbon fiber into the mix. The new composite heats up more easily, flows faster for speedier printing, and results in a stronger product. The new composite is patent-pending and work is underway to refine the material and find other ways to process it. The ORNL team also included Sietske Barnes, Christopher Bowland, Kelly Meek, Kenneth Littrell and Jong Keum. The research was funded by DOE’s Office of Energy Efficiency and Renewable Energy’s Bioenergy Technologies Office.

“ORNL’s world-class capabilities in materials characterization and synthesis are essential to the challenge of transforming byproducts like lignin into coproducts, generating potential new revenue streams for industry and creating novel renewable composites for advanced manufacturing,” said Moe Khaleel, associate laboratory director for Energy and Environmental Sciences.

ORNL is managed by UT-Battelle for the Department of Energy’s Office of Science, the single largest supporter of basic research in the physical sciences in the U.S.

Related Content

-

How Additive Manufacturing Can Help, not Hinder, Injection Moldability of New Designs

Four cost drivers—design for moldability, mold-base size, internal componentry, polish/custom finishing—dictate the financial and processing success of a molded part design. Learn how 3D printing can assist this process, while also understanding its potential pitfalls.

-

Large-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.