Micromolder Makuta Adopts Carbon 3D Printing

Special printing process opens up new business for custom injection molder in functional prototypes and short runs of complex parts.

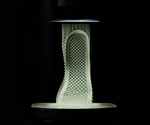

Makuta, a well-known custom micro injection molder in Shelbyville, Ind., is now a Certified Production Partner of Carbon Inc., supplier of 3D printing equipment and materials using Digital Light Synthesis (see Nov. ’18 Close-Up). Makuta (see Sept. ’15 On-Site profile) gains from this the ability to offer high-performance plastic parts prototyping and limited production runs with Carbon technology. “We were truly excited when we saw this additive manufacturing technology in action, and are now pleased to expand our business capabilities by being able to offer this service to our customers,” says Stu Kaplan, president of Makuta. (Kaplan is pictured here with a Carbon M2 printer and wearing Adidas Futurecraft 4D sneakers with midsoles printed in a carbon urethane elastomer.)

Makuta president Stu Kaplan with Carbon printer and wearing Adidas sneakers with 3D-printed insoles.

“The addition of Carbon digital manufacturing technology enables us to offer customers fast, cost-effective prototypes and limited production runs of small and complex parts, larger than the micro-sized parts we injection mold,” Kaplan adds. “Further, due to Carbon’s innovative technology, these are high-performance ‘working prototypes,’ with quality similar to injection molded parts and superior structural integrity and surface finish when compared with conventional 3D printing.”

Related Content

-

Medical Manufacturer Innovates with Additive Manufacturing and Extrusion Technology Hubs

Spectrum Plastics Group offers customers two technology hubs — one for extrusion, the other for additive manufacturing — to help bring ground-breaking products to market faster.

-

New Tool Steel Qualified for Additive Manufactured Molds and Dies

Next Chapter Manufacturing says HTC-45 — an optimized H-13 — will offer superior thermal transfer and longer tool life.

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.