Milacron Joins Organization for Machine Automation and Control (OMAC)

Along with its IIoT partner, ei3, Milacron is now part of a working group to establish best practices for remote access methods.

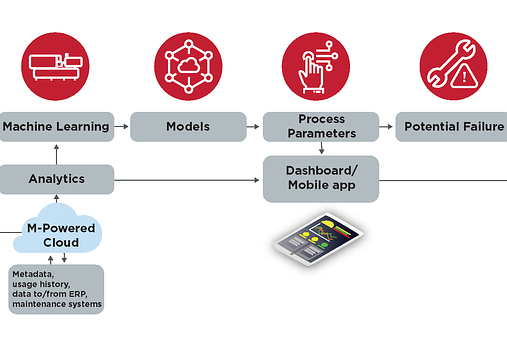

Milacron has joined the Organization for Machine Automation and Control (OMAC), which is currently working to establish the best practices for remote access methods. The company said customers’ use of the remote access capabilities of its IIoT platform, M-Powered, has been accelerating in the last 15 months, rising 70%.

Milacron stated that it saw a gap in industry requirements for secure remote monitoring services available on the marketplace, adding that M-Powered customers own their data, and it is Milacron’s job to keep data and assets secure.

The guidelines resulting from the OMAC working group are intended to establish a robust framework that will allows organizations to achieve their production goals while maintaining safety and security.

OMAC membership includes end-user manufacturers, OEM machine builders, system integrators, technology providers, and non-profit and government organizations. It has two working groups: Packaging and Manufacturing. Founded in 1999, ei3 provides a suite of IoT and AI applications designed for manufacturing companies to increase machine performance, reduce downtime, improve quality, and reduce energy consumption.

Milacron has joined the Organization for Machine Automation and Control to determine best practices for remote access.

Related Content

-

50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

.png;maxWidth=300;quality=90)