New Global Standard Aims to Harmonize Injection Molding Machine Safety

ISO 20430—the first international safety standard for plastics and rubber machinery—was published after more than seven years of collaboration by roughly 40 experts from machine makers, associations, and health and safety organizations hailing from 13 countries.

ISO 20430 for injection molding machines will allow machine manufacturers to have one global standard for machines, eliminating the possibility of having to create different models for different markets, while also allowing countries that had no safety standard to apply an international one, according to Dr. Harald Weber of the German Plastics and Rubber Machinery Association (VDMA). Using the existing European EN 201 standard as a basis, the new international ISO standard was created via collaboration among 40 experts across machine makers, trade associations and health and safety organizations from 13 countries.

From the U.S., Weber said Stan Glover of Zeiger Industries represented the Plastics Industry Association (PLASTICS). In addition, Weber noted that experts from Milacron and Arburg’s U.S. subsidiary, among others, represented U.S. interests.

“The most important thing is the harmonization of the existing international standards, so that machine manufacturers do not need to build different versions of the machines,” Weber told Plastics Technology, citing as an example the U.S. market’s prior requirement for an additional mechanical restraint—known as the jam bar.

Covering 148 pages and created by the ISO/TC 270 technical committee, the document, according to ISO, “specifies the essential safety requirements for the design and construction of injection molding machines for the processing of plastics and/or rubber and provides information for their safe use.” ISO notes that the standard is only applicable to injection molding machines with hydraulic and/or electrical drives for platen movement (no manual presses).

Weber told Plastics Technology that the new standard also took into consideration technological progress by machine makers, including the continuous developments and improvements of safety aspects. In particular, the group looked at newer machines’ ability to perform specific machine movements, which were previously not allowed, in special control functions like maintenance or setup in a manual mode when the machine’s door is open.

“With the described safety concept, these operations can be carried out safely and do not give incentives for manipulation of the safety system,” Weber said. “A too-safe machine, which cannot be operated, becomes unsafe.” Weber also noted that annexes within the document describe different solutions that have been completely revised, making them clearer and inclusive of additional solutions, like the use of contactless position detectors.

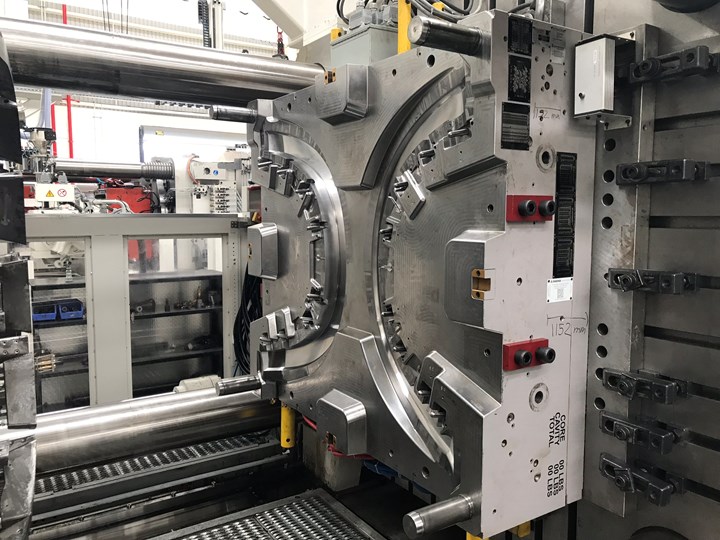

The new ISO 20430 injection molding machine safety standard is the first international standard for plastics and rubber machinery—seeking to harmonize existing disparate standards.

Related Content

-

How to Stop Flash

Flashing of a part can occur for several reasons—from variations in the process or material to tooling trouble.

-

Improve The Cooling Performance Of Your Molds

Need to figure out your mold-cooling energy requirements for the various polymers you run? What about sizing cooling circuits so they provide adequate cooling capacity? Learn the tricks of the trade here.

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

.png;maxWidth=300;quality=90)