Novel Washable PE-Based Health Mask Produced Via Thermoforming

Responding to coronavirus outbreak, Orbis is offering its BiOAID mask technology to interested thermoformers.

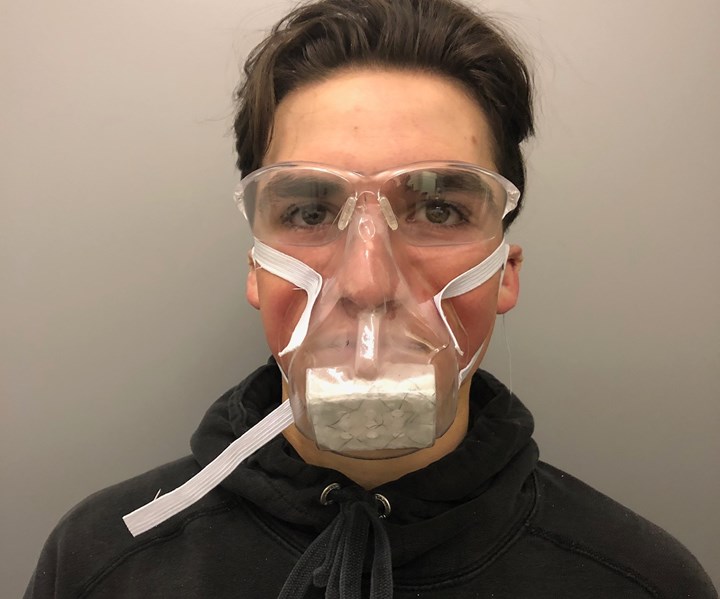

A unique thermoformable health mask with a PE-based shell and replaceable HEPA-type filter with some barrier material added to each side has been developed as an alternative to melt-blown PP N95 masks by Orbis (bioaid.us), Mill Valley, Calif. Co-founder and co-inventor Marcus Hays started up Orbis to develop in-wheel electric drivetrain systems for automakers, such as the patented Ring-Drive system comprised of wheel, brake and motor. Hays says he has opted to temporarily pivot to developing health masks after an assessment of available materials, such as PE sheet which is plentiful and familiar to many plastic thermoforming companies.

Orbis is willing to provide tools, dies and manufacturing instructions to interested thermoforming companies who engage in a "nominal" license royalty program. Hays explains that initially, they have opted to launch the BiOAID masks with contract-based manufacturing partners to ensure a fully-vetted and effective product at launch.

While not yet N95-certified, Hays expects that it soon will be. “We’ll pivot to licensing agreements in 45 days which at that point will be supported by a much deeper understanding of the market, our customers and our licensee’s needs. Thermoformers have a crucial role to play in helping to protect people’s health and livelihoods, and a nominal licensing fee that serves as an economic trigger for this industry to enter the mask market—and quickly-- is one way the world can get back to normalcy sooner rather than later.”

In terms of the materials used, Hays said they looked at both supply chain availability and material flexibility, which bears directly on comfort and face-seal performance—the latter being crucial for NIOSH and FDA standards. As such, the current BiOAID mask shells are produced from LDPE and PVDF sheet. “However, we are planning to use PET for the filter cartridge retaining clip This will not require more than a pair of dimple fabrication steps to manufacture, keeping the price of manufacturing low.”

As for the material used in the HEPA-type filter of the mask, Hays says any HEPA or MERV13-rated material (common to vacuum cleaner bags, and furnaces and typically made of borosilicate glass fibers, or PP fibers bound together with up to 5% acrylic binder) has been shown to be nearly as effective as a melt-blown PP N95. HEPA material is regarded as a relatively effective medium for capturing viruses—particularly if the virus is attached to larger carrier particle like aerosolized mucous or saliva. Adds Hays, “The BiOAID mask has the advantage of a replaceable filter, which can be made from many variations of known, effective filters. This helps ensure that the supply of filters is equal to the supply of thermoplastic mask shells, to keep up with demand for the BiOAID. Important, considering how unpredictable material sourcing is at this juncture.”

The front of the BiOAID mask shell is perforated with breathing holes backed by a two-inch square of common HEPA air filter material. Importantly, the BiOAID mask can be washed with soap and water or in the top rack of a dishwasher, unlike conventional N95 respirators. That reusability should help lower effective cost, which Hays said will be in line with other N95 respirators when produced at volume.

Asked whether the holes in the mask are formed as part of an inline trim process or next-step trimming, Hays says that initially, in-house production has depended on next-step trimming. “However, we’re entering into contracts now with production houses capable of scaleup, which will add significant sophistication and efficiency. We have, however, developed and manufactured molds and cutting dies and cutting due methods to enable our contract partners to get to market faster.”

Related Content

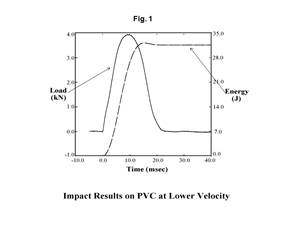

The Strain Rate Effect

The rate of loading for a plastic material is a key component of how we perceive its performance.

Read MoreUnderstanding Strain-Rate Sensitivity In Polymers

Material behavior is fundamentally determined by the equivalence of time and temperature. But that principle tends to be lost on processors and designers. Here’s some guidance.

Read MoreThe Effects of Temperature

The polymers we work with follow the same principles as the body: the hotter the environment becomes, the less performance we can expect.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhy (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read More