NPE2018 New Technology Focus: Process Cooling

Key themes in chillers at NPE2018 are efficiency, connectivity and transparency.

Efficiency, connectivity and transparency are key themes in process cooling, with new units applying the most efficient technologies for operations while sharing performance data with users.

Thermal Care has updated its central-chiller control systems with a new technology that continuously calculates the lowest allowable refrigerant pressure for any combination of operating conditions in order to maximize energy savings and provide more stable and smooth refrigerant pressure control, especially under varying load and condenser inlet temperatures.

Called Dynamic Lift, the technology also adds direct control of remote condenser fans or condenser water-regulating valves for added savings. According to Thermal Care, users will see an average 25% reduction in partial-load chiller energy use at a 50°F setpoint.

The company will also focus heavily on improved PLC controls, introducing its new Connex4.0 system, Thermal Care’s Industry 4.0 software. With the new control, users can control and monitor any Thermal Care equipment from any Internet-enabled device.

Novatec and Advantage Engineering are showing the DryTemp+, a patent-pending machine that combines a portable desiccant-wheel dryer and a fluid temperature-control unit (TCU) in a single footprint. The product is aimed at processors that don’t dry centrally.

The unit features a 7-in. touchscreen Siemens pendant PLC, which accesses both drying and mold-temperature-control parameters. The PLC can provide trending and data logging and will be Ethernet-equipped so it can be used for QC logging of jobs with resin, mold temperature, and drying parameters recorded.

Wittmann Battenfeld is showing the Tempro Plus D mold-temperature controller (TCU) and its Flowcon Plus unit for monitoring and controlling water temperature and flow in individual mold circuits. The Flowcon Plus is now available as a stand-alone unit for use with any brand of injection machine.

Engel is using NPE2018 as the North American launch of its iQ flow control software. Considered the next step in Engel’s bid to eliminate cooling errors, which the company believes have a disproportionate impact on scrap, iQ flow control builds on Engel’s flomo electronic water manifold system and e-flomo, which automatically sets the required flow rate for each temperature control circuit. New iQ flow control software networks the temperature-control unit (TCU), e-flomo, and injection machine together. Based on the measured values determined by e-flomo, iQ flow software controls the TCU’s pump speed on demand.

Burger & Brown Engineering Inc. highlights the TracerVM platform. The TracerVM Bluetooth Interface collects, transmits and saves flow and temperature data from up to eight TracerVM Base flowmeters installed in mold-cooling circuits. TracerVM Base Flowmeters purchased separately can be connected via cable to the TracerVM Bluetooth Interface.

The TracerVMA with AutoReg is a new automatic flow regulator that automatically adjusts flow rate to the required user-selected volume, regardless of changes in line pressure. This results in a more consistent flow rate with more control over cooling-water conditions in critical molding situations.

Also making a U.S. debut from Piovan’s Aquatech brand of industrial cooling is the Easycool+ line of air- and water-cooled chillers; along with Aryacool, a dry cooler that can meet the needs of various industrial processes; and DigitempEvo, which Piovan describes as its flexible heating/cooling solution.

Frigel’s line of Microgel machine-side chiller/TCUs with digital controls now lets users capture, display and record historical process-cooling energy data. In addition to energy consumption, the Microgel’s digital controls let processors review temperatures, pressures and flow rates. All operating data are stored in a historical log and are accessible via touchscreen. Processors can use the information to adjust the unit for specific molding conditions and optimal efficiency.

Thanks to what it calls the most efficient fan technology in the industry, AEC says its new High Efficiency central chiller can deliver users up to 60% in average energy savings. The chiller utilizes electrically commutated (EC) fan motors, which AEC says are more efficient than variable-frequency drives (VFDs) and fan staging across the entire load spectrum. Compared with VFD-controlled compressors, AEC says the High Efficiency central chiller is more efficient and less complex. It generates the biggest savings when running between 40% and 80% capacity.

AEC will also present a “Hybrid” freeze-proof adiabatic cooling system. This technology combines dry-air cooling during the cooler months of the year with fluid cooling during warmer months. AEC says the Hybrid adiabatic cooling system saves up to 95% in water use annually compared with a traditional cooling tower or a closed-circuit fluid cooler. Pulling outside ambient air across coils to remove heat when outside temperature is cool enough, the system only turns on fine misting nozzles when needed.

Mokon has at its booth expanded line of its Iceman SC Series portable chillers, now offering units with cooling capacity up to 50 tons. Mokon says this larger size will allow customers to consider portable units for their cooling needs versus having to jump to larger, immobile central systems. The Iceman SC Series, which utilizes scroll compressors and air- or water-cooled condensers, now ranges in capacity from 0.5 to 50 tons. The fluid temperature range goes from 20 F to 65 F.

Related Content

Troubleshooting Leaky Temperature-Control Units

Learn the causes, symptoms and remedies for TCU leaks to keep these vital contributors to plastics processing up and running longer and more efficiently.

Read MoreIs Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

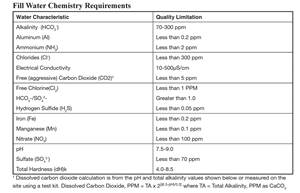

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

Read MoreHigh-Temperature, Low-Flow Indicator for Mold-Cooling Applications

Burger & Brown Engineering has released a new high-temperature low-flow indicator to monitor flow inside critical, restricted cooling paths such as those with bubblers or baffles.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreRead Next

How Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More