Paper IML Trims PP Tub to a Skeleton

Stiff paper in-mold label provides topload strength while allowing removal of 76% of the PP in injection molded food tubs.

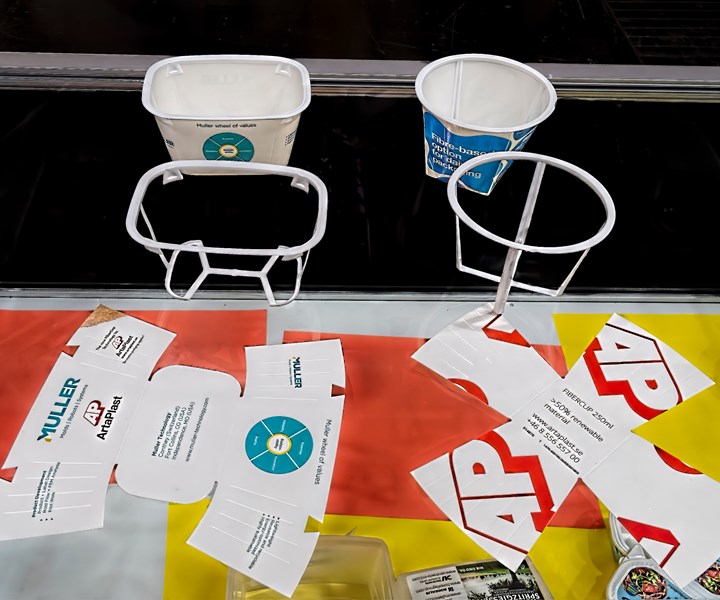

A novel packaging concept exhibited at October’s K 2019 fair in Düsseldorf promises to cut costs and perhaps environmental footprint. Displayed by Swiss-based Muller Group (formerly Mold & Robotics Group), specialists in molds and automation for thin-wall packaging and in-mold labeling (IML), this concept eliminates 76% of the PP in an injection molded tub, replacing it with a thick paper label that becomes the structural sidewall. According to Taras Konowal, director of sales and marketing for packaging automation provider Muller Technology Colorado (formerly CBW Automation), this approach not only saves money on PP resin, but the paper label is also much less expensive than a plastic in-mold label. What’s more, topload strength is actually increased by this construction, he says (muller-technology.com).

Muller Technology showed how a stiff paper in-mold label can provide topload strength while eliminating 76% of the PP in a 250-ml food tub.

Two commercial applications of this concept—for cottage cheese and yogurt—have been launched in Europe by Arta Plast of Sweden (artaplast.se). The label was supplied by Stora Enso of Finland and Sweden (storaenso.com). Its Fiber Cup material is paperboard coated on both sides with a thin layer of PP. It contains >50% renewable material, according to Stora Enso, and is described as “recyclable.” IML experts interviewed at K 2019 questioned whether the overall IML package would more appropriate for the paper or plastic recycling stream.

Related Content

-

Expanded Line of Automated 3D Laser Scanning Systems

OGP’ ShapeGrabber family now includes vertical-axis ShapeGrabber Ai320 benchtop and Ai620 and Ai820 floor models.

-

Hot Wash Systems for Recycling Polyolefins

Herbold can configure wash plants for polyolefins that can produce high-quality, food-grade recyclates.

-

Stratasys to Acquire Covestro’s Additive Manufacturing Materials Business

This acquisition will result in Stratasys having an expanded portfolio of differentiated materials in stereolithography, DLP, and powders.