Pilot Plant to Produce Multipurpose Bioplastic from Soy Residue

Four Finnish companies in collaboration to develop the first process to produce compostable bioplastic from food and feed production side streams.

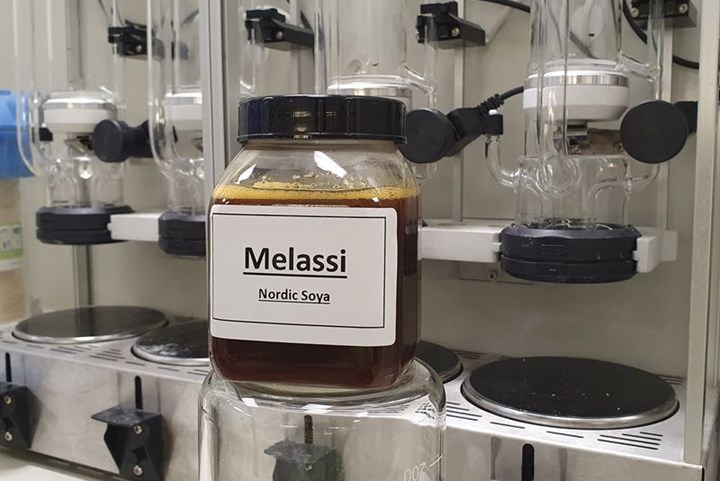

A bioplastic plant to be built in Uusikaupunki, Finland, will be piloted on an industrial scale to produce what is said to be the world’s first process to product compostable bioplastic from food and feed production side streams. Four collaborating Finnish companies—Finnfoam Oy, Brightplus Oy, VTT Technical Research Centre of Finland and Nordic Soya, have jointly explored the potential of soy molasses, i.e. soy processing side stream, as a raw material of the future. Partly funded by Business Finland, the research project took four years.

In connection with Nordic Soya Oy, the largest soy protein concentrate processing plant in the E.U., the pilot plant will be built during 2021-2022, with full-scale operation scheduled by the end of 2023.Responsible for coordinating the project is Brightplus Oy which produces new green chemistry innovations together with its partners that can be tested at the pilot plant. Said technology director Jarrko Leivo, "It is a major technological step forward that side streams that are unusable in food production can now be used to produce responsible high value bio-based products. Depending on the application, we can modify the properties of the biomaterial, such as its transparency and thermoformability, or improve its chemical resistance and reusability. We are now looking for pioneer-minded partners interested in this great technology with whom we can develop more innovative applications for this biopolymer.”

Said initiator of the project and CEO of Finnfoam Henri Nieminen, "The process developed as an outcome of this cooperation project is the first in the world to produce an ecological lactic acid polymer from the side streams of soy production. This way we can offer a sustainable alternative to sugar and corn based polylactic acid (PLA).”

Not suitable for food, soy molasses have previously been disposed of by incineration. Producing biomaterials from side streams of food production also improves the food production value chain.

Nordic Soya Oy uses soy grown in Europe in its Uusikaupunki plant. Soy molasses left over from its processing has been used as the raw material in the research. This Finnish innovation combines synthetic biology, chemistry and material technology in what is said to be a completely new way.

Said Tiina Nakari-Setälä, VTT’s v.p. of strategy and business intelligence,"This project is both an excellent example of what expertise in industrial biotechnology can achieve and a triumph in converting a challenging industrial residue into a higher value product using microbes. This endeavor required significant efforts in technology at various stages of the process. It particularly made use of VTT's expertise in synthetic biology, the modification of microbes and optimization of bioprocesses.”

In the future, this Finnish sustainable concept for the development and production of biobased raw material can be extended to new markets where soybean is processed for food and feed production. Bioplastic produced from the residues of soy processing has huge potential as a scalable export product in circular economy. Globally, residues from soy production could produce around 22 million tons per year (44 million lb/yr).

Also known for its medical applications, bioplastic is also ideal for, e.g., the manufacture of various compostable packaging applications and 3D-printing filaments. Finnfoam intends to use the new bioplastic in the production of thermal insulation for buildings. Its ecological quality is enhanced by the fact that thermal insulation also serves as a carbon sink, thus helping to reduce the carbon footprint of buildings.

Related Content

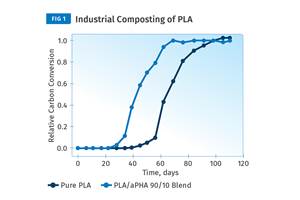

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreCJ Bio’s Amorphous PHA Demonstrates Excellent Biodegradability in Marine environment

The tests of the bioplastic, a semi-crystalline PHA and a PLA were conducted by the national Korean testing agency (KCL)

Read MoreBlend Amorphous PHA with PLA to Improve injection Molded Part Properties

Adding aPHA to PLA can boost a range of mechanical properties and expedite composting. Here are the details as well as processing guidelines for injection molding the blends.

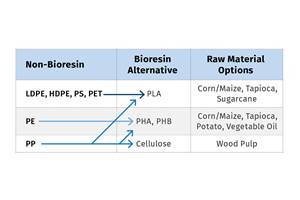

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreProcessor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

Read More