Polykar Adds Third W&H Multi-Layer Line

New Optimex adds seven million lb of capacity.

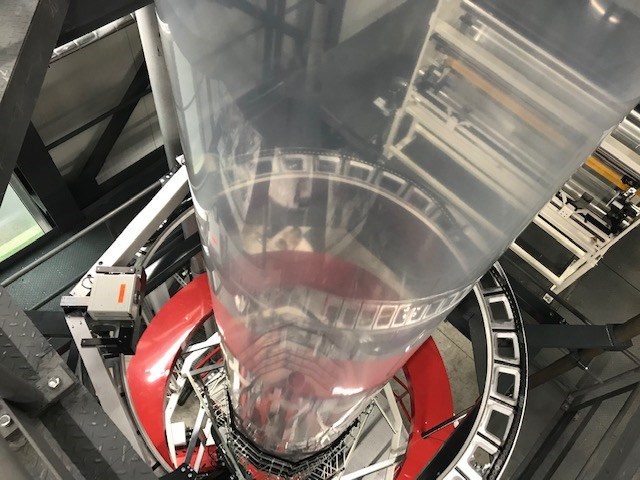

Blown film processor Polykar announced that it has installed and commissioned a third Windmöeller & Höelscher (W&H) Optimex line at its Montreal plant. Polykar makes polyethylene film, certified compostable bags, garbage bags, and food- and industrial-grade liners.

The Optimex system will give Polykar the flexibility to produce a broad range of three-layer film films at high outputs while ensuring maximum quality and faster product changeovers, the processor says.

Polykar says its $3 million investment will support the increasing demand from North American customers for high quality and complex PE-based film structures. The additional line also increases the processor’s multi-layer capacity to 22 million lb and will result in quicker product turnaround, the company notes.

Commenting at the machine start up, Amir Karim, president of Polykar, notes, ‘’We are very excited to see our third Optimex line installed, not only for the much-needed increase in production, but also for the addition of half a dozen new technical positions in our coextrusion department, which will help us ramp up our share of the convertor film market.’’

Polykar’s first Optimex machine was installed in 2014, and was the 100th such line sold worldwide by W&H. “Looking back, I remember convincing Polykar that the Optimex would be a consistent and reliable machine that would allow them to produce high-quality coex films,” recalls Andrew Wheeler, president of W&H in North America. “Now, three lines in, we are trusted partners and friends. For W&H, it’s very satisfying to work with another family-owned company that puts as much value on the quality of machinery as we do.”

Related Content

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

Filtration System Helps Film Processor Manage Recycled Material Mandates

Global film processor RKW teams with Nordson to enable it to process blown film with high recycled content.

-

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

.png;maxWidth=970;quality=90)