Resin-Drying Icon Sears Dies at 78

40-year industry veteran was founder and president of Dri-Air Industries.

Charles Sears, founder and president of resin-drying machine builder Dri-Air Industries, E. Windsor. Conn., passed away on August 5 after a year-long battle with cancer. He was 78.

Known to everyone as simply Charlie, Sears started Dri-Air in 1985. Before that he worked for Polymer Machinery, Automated Assemblies and Nelmor (AEC) in a career in plastics machinery that extended well beyond 40 years. Charlie received his BSME from Northeastern University and MME from RPI.

Under his guidance and leadership, Dri-Air quickly became a leading supplier of drying systems, with his business regularly growing by double digits. Those who knew him, including this editor, would describe him as a family man whose personal and business life were guided by integrity, honesty, faith, dignity, humility, and plain-old decency. If Charlie had a credo, it was, “Do what’s right.” Charlie was a masterful story teller—they were always funny—and I don’t think I ever heard the same one twice. He’d almost always punctuate them with a hearty laugh.

Charlie was a family man and not just in the strictest sense of the word. He and his long-time wife and business partner, Esther, were together constantly at trade shows and a myriad of other industry events. They radiated warmth and affection and kindness. If I was on a business trip, away from home, missing my family, and feeling a little blue about it, everything seemed better as soon as I saw Charlie and Esther.

Charlie was extremely savvy technically. He also liked to read magazines. I know he read Plastics Technology because he called me often about articles. I’d see on my caller ID that Charlie was buzzing, and I’d answer, a bit skittish, “Ok Charlie. Let’s get this over with. What did I do?”. After one of those hearty chuckles of his, he’d tell me what I did. You see, Charlie was a man with opinions. About business in general, and the plastics business in particular. (Oh, and about politics, politicians, bureaucracy, education, etc.) And, well, he wasn’t shy about sharing them. But the thing with Charlie was this—far more often than not his calls were to comment and offer support on something he read and liked or agreed with. Of course, there were also calls that went something like this: “You wrote a big article about something that didn’t work when it was first tried 30 years ago. And guess what, it won’t work now either.”

A press release distributed after he died rightfully described him as “a noted authority on the science of drying technology and applications (who) held several patents.” Customers were part of Charlie’s extended family too. The press release also noted that to Charlie, “Customers represented a relationship that you have to earn and respect.”

This industry was founded on the blood, sweat and ingenuity of entrepreneurs who looked at plastics as a business filled with opportunity and built companies to meet a growing need. Charlie was a prime example of one such entrepreneur, and his passing made me realize there are only a few left.

Dri-Air employs 27. Esther manages the accounting and Charlie’s son, Jason, who has been with the company 27 years, is in charge of the company operations. In addition to Esther and Jason, Charlie is survived by daughter Wendy O’Seep, her husband Greg and their two children Austin and Carolyn; as well as Jason’s wife Rebecca along with their two sons: Caleb and Josh.

Charlie was a giving man in life, and now in his death, as well. In lieu of flowers, the family would prefer to see donations in honor of Charlie to support the next generation of Plastics Engineers through scholarship support at UMass Lowell in his name, or to support the Syracuse Plastics Collection at the University Library.

Where the former is concerned, please mail donations made out to:

The UMass Lowell Plastics Scholarship Fund

UMass Lowell, Plastics Engineering Department

One University Ave, Lowell, MA 01854

Attention: Gail Sheehy

For additional information and other ways to make a donation in honor of Charlie at UMass Lowell, please contact Sally_washburn@uml.edu; 781-861-9486.

To donate to the Syracuse Plastics Collection, you can send a contribution to “Syracuse University Libraries” with the words “Plastics Collection” in the memo line of the check.

Syracuse University Libraries,

222 Waverly Ave., Syracuse, NY 13244

Attention: Bianca Breed

You can also donate to this cause online at GiveToSULibraries.syr.edu. Choose “SU Libraries Dean’s Fund” and check the box for “My Gift is a Tribute” “In memory of” and write in Charlie’s name.

Related Content

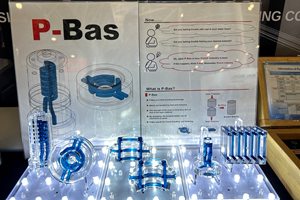

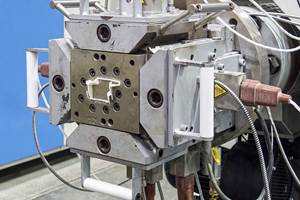

Bonding, Sintering Tech Advances Metal Bonding for Mold, Die Components

NPE2024: Punch Industry USA exhibits P-Bas, intended to replace the use of 3D printers when producing mold and die components, as well as a variety of mold component supplies.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

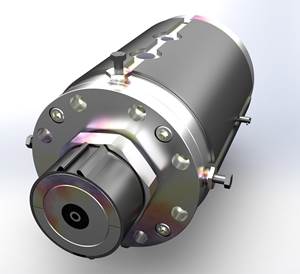

Read MoreSpiderless Pipe Die Touts Material Savings

Capable of providing a finished extrusion with OD from 2 in.-15 in.

Read MoreAuto-Profile System for Blown Film Rotating Dies

NPE2024: New technology can slash gauge variation by 50%.

Read MoreRead Next

Understanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More