S-BOPP Film Maker Opts to Use SABIC's Renewable PP

Irplast’s new NOPP (Natural BOPP) films are made with SABIC’s certified renewable PP derived from biobased feedstock.

Italy’s Irplast S.p.A., a global producer of simultaneously bi-oriented polypropylene film (S-BOPP) for the manufacture of printed adhesive tapes, wrap-around labels for the food, beverage dairy, personal & home care markets and also for multi-pack solutions, has selected certified circular and certified renewable PP from the Trucircle portfolio of SABIC (U.S. office in Houston) for its new S-BOPP film solutions.

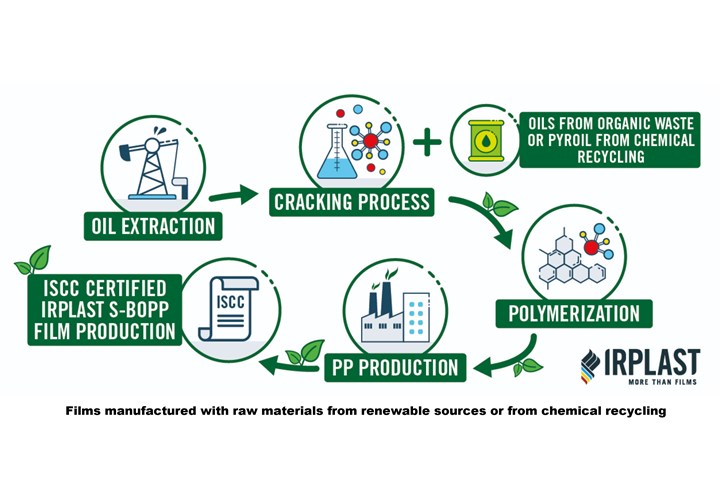

Irplast, known for its advanced LISIM stretching technology applied to BOPP that is done in one-step vs. the standard two-step process, has always focused on sustainability with important investments to reduce thickness and to save raw materials and energy. The company’s new innovative and sustainable S-BOPP film portfolio received ISCC certification at the end of 2019, which guarantees the solidity of the chain of custody right through the life cycle, from raw material production to packaging supplies. This new generation of BOPP film include NOPP (Natural BOPP), which is made from certified renewable SABIC PP derived from biobased feedstock.

The resulting S-BOPP films reportedly comply with rigorous food contact regulations and are 100% recyclable in normal polyolefin waste separation streams. Said SABIC’s circular economy leader Mark Vester, “The materials from our Trucircle portfolio offer drop-in solutions and we are very happy to collaborate with Irplast and support them to deliver sustainable solutions to the packaging industry. With our certified circular and renewable polymers, we are aiming to create a value chain where SABIC and key downstream customers like Irplast collaborate to recycle mixed post-consumer plastic back to the original polymer for packaging or other applications, thereby enabling the circular reuse of the planet’s natural resources.”

SABIC’s certified renewable polymers reportedly are high-quality virgin polymers, based on second-generation, biobased feedstock. Like SABIC’s certified circular polymers, its certified renewable polymers have been accredited through the International Sustainability and Carbon Certification (ISCC PLUS). SABIC uses feedstock which is not in competition with the food chain and are not of animal origin, such as the waste vegetable oils, currently available as a recovered by-product of the responsibly managed forest industry. All the films in Irplast's S-BOPP portfolio are ISCC certified and are said to offer identical technical properties equivalent to standard versions, offering brand owners and packaging suppliers truly sustainable packaging solutions.

The other sustainable option being developed by Irrplast involves the manufacture of LOOPP films made from SABIC’s certified circular polymers that are made from recycling of low quality, mixed plastic waste otherwise destined for incineration or landfill. The resultant certified circular polymers reportedly are of equal quality to virgin polymers with outstanding mechanical, processing properties and purity. Said Irplast’s sustainability manager, “We firmly believe that sustainable growth must become a priority for businesses producing and converting plastic packaging materials. As a packaging producer, we are well aware of our responsibilities in making the 2030 Sustainable Development Goals a reality and we are very committed to the challenge. We have undertaken a gradual but determined path, consistent with the development of new materials according to the guidelines of the EU Packaging and Packaging Waste Directives. Therefore, we have brought out two new innovative product lines in collaboration with SABIC, one to reduce the carbon footprint of BOPP flexible packaging, while the other introduces the possibility of entering the circular economy, being progressively mandated by legislators worldwide.”

Related Content

Latest Data on Bottled Water Shows Continued Strong Growth

Bottled water’s volume surpassed soft drinks for the first time in 2016 and has done so every year since.

Read MoreGerdau Graphene Launches “First” Graphene-Enhanced PE Additive Masterbatch for Extruded Packaging and More

The company has also partnered with conglomerate Sumitomo Corp. for distribution of its graphene-enhanced masterbatches in Japan.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreAt NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.png;maxWidth=300;quality=90)