Simulation Software Speeds Mask Development

Sigma Engineering partnered with Arburg and others to expedite the design and optimization of a molded LSR mask, using simulation to determine mold setup, filling calculations and thermal layout in 24 hours.

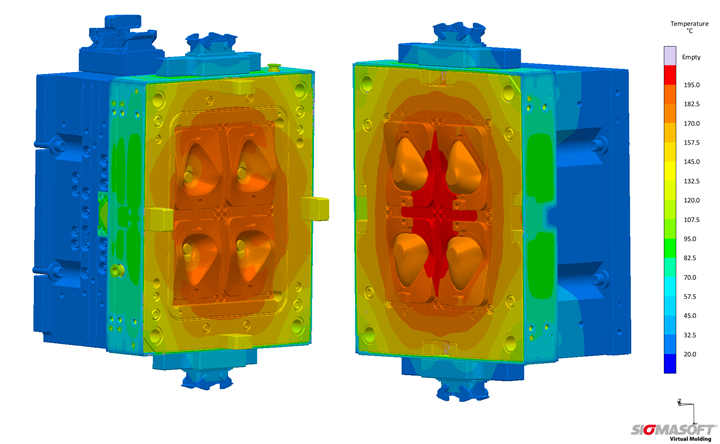

Arburg and moldmaker Polar-Form Werkzeugbau GmbH worked with Sigmasoft to simulate the layout of the complete LSR mold in shortest amount of time and optimize the mold design for process-efficiency and robustness, according to Sigma’s Thomas Klein. In particular, the virtual molding software was used to evaluate gate location, venting, and cooling channels for the LSR tool. In addition, the program was able to predict the process parameters for the mask, including required curing time. This work ensured a tool that would not trap air and lead to defects.

Sigmasoft partnered with Arburg and Pro-Form on a project to rapidly design and manufacture an LSR mask for coronavirus protection.

For precise control of the mold’s temperature profile, the simulation determined that the number of temperature sensors in the mold should be increased to six and it optimized their best location within the tool. Sigma noted that this allowed a focused regulation of the heating cartridges and determined optimal insulation of the mold to be as energy efficient as possible.

The simulation work was completed within 24 hours, according to Sigma. In the end, the mold produces four parts per cycle running the non-postcure LSR Elastosil LR 5040 supplied by Wacker at 180 C. The required symmetrical temperature profile of the four cavities was created and optimized in a simulation using optimal insulation, six temperature sensors and regulatable heating cartridges.

“The partners were under enormous pressure because everything had to run smoothly right away,” Klein said. “We are highly pleased that the mold ran in the computer first and mistakes were avoided. This way, an efficient process was created very swiftly.”

Sigmasoft’s mask simulation also determined the optimum temperature profile for the mold to promote LSR curing.

Related Content

-

Beacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

-

New LSR Cold Deck

Hot runner supplier Mastip used K 2022 to introduce the customized and valve-gated Aquilo liquid silicone rubber (LSR) cold deck.

-

Slimmer All-Electric Press Debuts

A slimmed-down version of Engel’s all-electric, e-mac injection molding machine is among eight displays, which also include LSR micromolding, quick mold changes and a cube mold.