Start-Up Company to Accelerate Development of Renewable Feedstocks

Trillium Renewable Chemicals to advance technology for production of such feedstocks as acrylonitrile for use in ABS and other plastics.

A new start-up company, Trillium Renewable Chemicals, Birmingham, Ala., plans to make chemicals from renewable feedstocks, including acrylonitrile for ABS with a net-zero footprint according to CEO Corey Tyree. “This technology can improve supply chain security and GHG (greenhouse gas) footprint of ABS makers,” he said, as one example.

The new start-up was jointly created by Belgium-based venture capital and investment firm Capricorn Partners and Southern Research (SR), an independent nonprofit, scientific research organization with more than 400 scientists and engineers working across three divisions: life science, engineering, and energy & environment. Headquartered in Birmingham, with additional laboratories and offices in Frederick, Md., and Houston, SR supports related industries with independent research on behalf of commercial and government clients, objectively assessing new technologies and providing process development support. It also pursues entrepreneurial and collaborative initiatives to develop and maintain a pipeline of intellectual property and innovative technologies that positively impact real-world problems.

Trillium Renewable Chemicals’ pilot plant to produce renewable acrylonitrile and glycols

SR has exclusively licensed its patented chemical manufacturing platform to Trillium to accelerate commercial development of this new technology which converts renewable feedstocks, such as sugar or glycerol to chemical products like acrylonitrile, propylene glycol, and acrylic acid. Said Amit Goyal, lead inventor from Southern Research: “The Southern Research team developed an innovative, elegant thermo-catalytic process that utilizes biomass derived sugars or glycerol, allowing for the use of a variety of biomass feedstocks, to produce acrylonitrile and other co-products. This process has the potential to improve economics and the overall environmental footprint of downstream products that utilize acrylonitrile as a raw material.”

Said SR’s COO Michael Catalano, “Southern Research is excited to team up with Capricorn Partners to further the development of our patented technology. With the foundation of Trillium and focused management, we will be able to maximize the commercial potential, which is the ultimate goal and in-line with our strategy to monetize intellectual property for re-investment in future scientific endeavors.”

Trillium and Southern Research will continue to work jointly on the process development, while Trillium will team up with strategic partners for the scale up and deployment of the technology. Said Tyree, “Trillium will demonstrate the commerciality of this technology. Local production from renewable resources can meet the growing demand for green chemicals and offer stable pricing and a more secure supply chain. The market interest is there. To address it, the industry needs enabling technologies such as the catalyst discovered by Southern Research.”

Capricorn Partners has invested from its Capricorn Sustainable Chemistry Fund. The proceeds will be used to scale up the process for the manufacturing of acrylonitrile and glycols. Said Wouter Van de Putte and Rob van der Meij, of Capricorn Partners, “We spotted the Southern Research Technology over two years ago and have been following the development closely as well as exploring market opportunities in Europe and the USA. This type of ‘green drop-in” molecule technology has a great advantage over new ‘green’ molecule developments in that the applications are already fully developed.”

Related Content

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

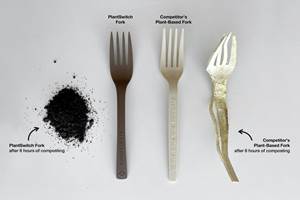

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More