Walmart Commits to New Plastic Packaging Waste Reduction Initiatives

The company is working with suppliers to expand efforts to improve the sustainability of its private brand product packaging, with an emphasis on increasing recyclability and making it easier for customers to recycle.

Walmart issued a new set of plastic waste reduction commitments that is focused on its massive private brand program. The new commitments, announced at Walmart’s annual supplier forum, are expected to impact over 30,000 SKUs. The move is focused on the retailer’s private brand packaging, building upon existing efforts to reduce plastic waste in Walmart U.S. and Sam’s Club operations, and encouraging national brand suppliers to set similar packaging goals. At the supplier forum, Walmart executives highlighted that the company is working with suppliers to expand efforts to improve the sustainability of its private brand product packaging, with an emphasis on increasing recyclability and making it easier for customers to recycle.

Walmart announced that it will work with its U.S. private brand suppliers on the following commitments:

- Seek to achieve 100 percent recyclable, reusable or industrially compostable packaging for its private brand packaging by 2025;

- Target at least 20 percent post-consumer recycled content in private brand packaging by 2025;

- Label 100 percent of food and consumable private brand packaging with the How2Recycle label by 2022;

- Work with suppliers to eliminate the non-recyclable packaging material PVC in general merchandise packaging by 2020; and

- Reduce private brand plastic packaging when possible, optimizing the use to meet the need.

Walmart also encouraged it’s national brand suppliers to make similar packaging commitments through the retailer’s Project Gigaton platform. The retailer has also introduced a new recycling playbook designed to provide information to companies pursuing recyclable packaging and recycled content goals. The recycling playbook gives overviews on what type of plastic packaging is more easily recyclable and provides information on recycling challenges for certain packaging materials. This new recycling guidance is a supplement to Walmart’s existing sustainable packaging playbook that offers information on sustainable packaging best practices such as optimizing packaging design and using consumer-friendly recycling labels.

Some of the retailer’s current efforts to reach this goal include:

- Offering low cost, high quality alternatives for single use plastic consumable products such as straws, cutlery and disposable tabletops;

- Recycling shrink wrap in most markets—151 million pounds of plastics were recycled globally in 2017;

- Providing access to in-store plastic bag and film recycling bins for customers; and

- Encouraging suppliers to include the How2Recycle label on pack—last year more than 800 Walmart private label suppliers participated.

“As a global retailer that has set an ambitious aspirational goal to create zero waste, we fully recognize that reducing plastic waste by increasing packaging circularity is an area where Walmart can lead,” said Laura Phillips, senior vice president for global sustainability at Walmart. “Today’s announcement marks another key milestone in our ongoing journey of working with our private brand and national brand suppliers to deliver access to high-quality, sustainable products as part of the Walmart everyday low price promise.”

In being a signatory to the G7 Oceans Plastics Charter and the New Plastics Economy Global Commitment being led by the Ellen MacArthur Foundation, in collaboration with the UN Environment, Walmart is working globally to reduce plastic waste within its operations and throughout its value chain. By the end of 2017, Walmart diverted from landfills 81 percent of unsold products, packaging and other waste materials in the U.S.

Related Content

Inside the Florida Recycler Gearing Up to Take on Scrap at NPE2024

Hundreds of tons of demonstration products will be created at NPE2024 next spring. Commercial Plastics Recycling strives to recycle all of it.

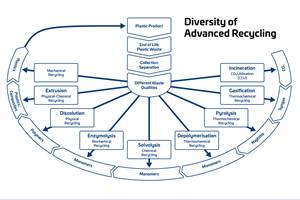

Read MoreAdvanced Recycling: Beyond Pyrolysis

Consumer-product brand owners increasingly see advanced chemical recycling as a necessary complement to mechanical recycling if they are to meet ambitious goals for a circular economy in the next decade. Dozens of technology providers are developing new technologies to overcome the limitations of existing pyrolysis methods and to commercialize various alternative approaches to chemical recycling of plastics.

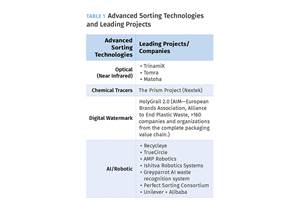

Read MoreRecycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

Read MoreRecycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MoreRead Next

Why (and What) You Need to Dry

Other than polyolefins, almost every other polymer exhibits some level of polarity and therefore can absorb a certain amount of moisture from the atmosphere. Here’s a look at some of these materials, and what needs to be done to dry them.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More