WEIMA Partners with City of Charlotte in Progressive Recycling Initiative

Envision Charlotte Innovation Barn tackles take-away containers.

Polypropylene take-away containers at the Envision Charlotte Innovation Barn, a progressive recycling initiative in Charlotte, N.C., are being recycled with the help of a table-top shredder and granulator supplied by recycling equipment supplier WEIMA America. During the pandemic, multiple organizations washed and collected the used containers, and Innovation Barn began to take on the task of shredding them and recycling them on-site.

WEIMA and Innovation Barn Envision Charlotte had initially equipped the facility’s plastics lab with a small, hand-fed pre-shredder to grind up the collected takeout containers. The material was then extruded in a tabletop extruder, and the product of this process was used as the filament in a 3D printer. That filament was used to create bricks that could be used in lieu of cinder blocks in some applications. The goal was to show a working example of how one plastic product can be reimaged into another useful plastic product, thus giving the takeout containers a second life as well as a purpose.

“We are so excited to partner with WEIMA to help us advance our circular economy goals! One of our priorities is to divert as much plastic as we can from the landfill and having a shredder like this allows us to turn high volumes of #5 plastic into flake that can be used to extrude, mold, or even turn into filament for 3D printers. We have been engaging the public, involving local companies, and hosting events to collect these materials, and with the help of WEIMA we are making a difference, said Amy Aussieker, executive director of Envision Charlotte Pandemic plastic pile-up.

In the summer of 2021, WEIMA lended the Innovation Barn a granulator with a sound enclosure to make their plastic lab more efficient. The WEIMA granulator was a huge help in this process, as the tabletop shredder was unable to handle such a large volume. Now that the shredder is installed, the stored containers are being shredded into reusable flakes much more efficientl. The lab can process significantly more plastic containers within the facility while continuing to educate school groups and Charlotte citizens about the process of reimagining plastic waste.

Said WEIMA North American marketing manager Audrey Brewer, “We knew immediately upon entering the Innovation Barn that WEIMA absolutely wanted to be a part of making Charlotte a greener city. Our company’s core values truly align with what Envision Charlotte is doing here, and we knew we could make the process easier by placing a granulator in their plastics lab. The impact of this project will be monumental and far-reaching, even beyond Charlotte. Other cities are modeling their own recycling programs by learning from what Envision Charlotte is doing. We're extremely proud of this partnership and excited to see where it's headed.”

Collection programs encourage proper recycling. Utilizing the city’s ever-present waste stream is vital to the perpetuity of the circular economy. A collection program was established for recyclables like aluminum cans, plastic bottles, and bubble wrap, to name a few. Nearby residents can register to receive unique bags that are tagged and registered to their household or business. They can fill these bags with sorted, clean materials that will be picked up as needed and delivered to the Innovation Barn for further recycling. If any contaminated or unsorted materials are found in the bags, the program will reach out to the household and remind them of the best way to recycle their products. After these reminders, if the contamination continues, the household will be unenrolled from the program. This program aims to educate the community and get them involved in embracing sustainability—and the citizens of Charlotte have been very receptive to this process!

On-site collection bins allow for more product to be reclaimed In conjunction with the bagged recycling program, community members are invited to drop off accepted recyclables 24 hours a day at either of the drop-off locations. There are bright pink collection bins outside of the Innovation Barn for this very purpose. According to Daniel Heaton, who is on staff at Envision Charlotte, the community has been excellent so far at cleaning and sorting these materials prior to drop-off. This makes it much easier for the staff to continue the recycling process once the materials are brought inside the warehouse.

Related Content

Fungi Makes Meal of Polypropylene

University of Sydney researchers identify two strains of fungi that can biodegrade hard to recycle plastics like PP.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

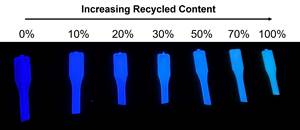

Read MoreFast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More