Additives: Cost-Efficient Metallic Colorants as an Alternative to Surface Coating and Electroplating

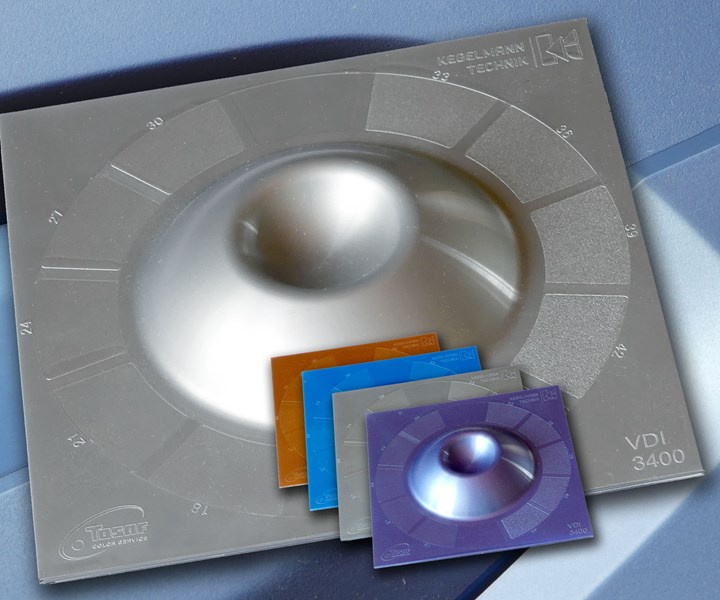

Tosaf’s new metal-like colorants based on special effect pigments not previously available and compounding know-how.

A series of new metallic color masterbatches reportedly put an end to the previously typical and undesirable streaks and similar surface defects on plastic parts from conventional colorants and are a cost-efficient alternative to surface coating and electroplating. Developed in Germany by Tosaf Color Service, a subsidiary of Israel’s Tosaf, a 30-year manufacturer of

plastics additives, masterbatches and compounds, they are the result of special effect pigments with a rheologically optimized geometry that have only recently become available in combination with Tosef’s compounding know-how.

The new colorants have been shown to meet the requirements for the cost-cutting, environmentally friendly use of components with brilliant metallic finishes in visible areas. They are available on different carrier systems and, at short notice, in customized shades. They are suitable for all transparent thermoplastics, such as PET and PC, whereby the brilliance increases with the degree of transparency. However, they can also be used in opaque plastics such as PC/ABS or PA/ABS blends.

According to Tosef, the further developed pigment technology makes a major contribution to the considerable reduction in the separation effects that are responsible for streak formation or color deviations, especially in critical areas such as weld lines, cross-sectional transitions or with distinctly three-dimensional, concave or convex contours. The main beneficiaries of this are suppliers to the automotive industry and other segments with extremely high-quality demands and with rapidly changing designs that are geared to individuality.

Depending on the demands, moldings produced with this masterbatch stand out through their color depth and outstanding surface gloss and also through a delicate structure when eroded molds are used. In many applications, they can replace coated or electroplated parts, which not only saves costs through the elimination of additional work steps, but also makes a considerable contribution to the preservation of the environment. Added to this is the good suitability of the single-sort parts for recycling

Said Tosef Color Service head of sales & marketing Andreas Kruschinski, head of Sales and Marketing at Tosaf Color Service, "These new special effect masterbatches are our response to a variety of demands from our customers that could previously not be met in this combination and to such perfection. For us, the most promising markets apart from automotive interior and exterior applications are office electronics, for example keyboards and laptop housings, as well as white goods in the form of large and small kitchen devices."

Related Content

-

How to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

-

Young Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

-

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.