Additives: New Additives for BOPP, Wire/Cable, FR Nylon

Dow Performance Silicones (formerly Dow Corning) has non-migrating slip additive for BOPP, an improved FR synergist for nylon; and a process aid for W&C.

At the recent Fakuma show in Germany, Dow Performance Silicones, a unit of DowDuPont Materials Sciences Div., Midland, Mich., presented three new and recently introduced silicone-based additives for quite different applications:

• Non-migrating slip agent for BOPP film: Dow Corning HMB-6301 Masterbatch delivers stable, long-term slip performance without migration. Filling a gap in the market, this unique additive allows BOPP and cast PP film to run about 30% faster in printing, laminating, and metalizing operations, according to the company. It also shows no migration of the slip agent—which can interfere with converting and affect the clarity of the film—after 18 months’ storage. Unlike other slip additives, HMB-6301 is added only to the outer layer of BOPP film. It is stable over time and temperature, so its slip properties are permanent (e.g., 0.2-0.3 CoF in film on film at 2-5 wt. %). The free-flowing pellet product is said to comply with EU and U.S. FDA food-contact regulations.

• FR synergist for nylon: Introduced last spring, Dow Corning 43-821 additive is described as a novel solution to the drawbacks of using phosphorus-based additives in glass-reinforced flame-retardant nylon 6 and 66 used in electrical/electronic applications. The phosphorus additives are nonmelting solids used at high loadings—typically 18-20%—

which can degrade the compound’s physical properties and flowability. Also, the phosphorus additives are acidic and can corrode connectors; and they are susceptible to accelerated aging that can cause embrittlement. New 43-821 Additive is a powder synergist for phosphorus additives (it’s said to work well with Clariant’s Exolit OP, for example) but it allows their loading to be reduced to 10-12%, which restores nylon’s mechanical properties and processability and reduces corrosivity by cutting down the total phosphorus content. It also can reduce total cost of the compound by at least 10%. A loading of just 2% 43-821 Additive with 10% aluminum phosphinate reportedly can achieve UL 94V-0 at 1.6 mm. Raising the phosphinate content to 13% meets V-0 at 1 mm.

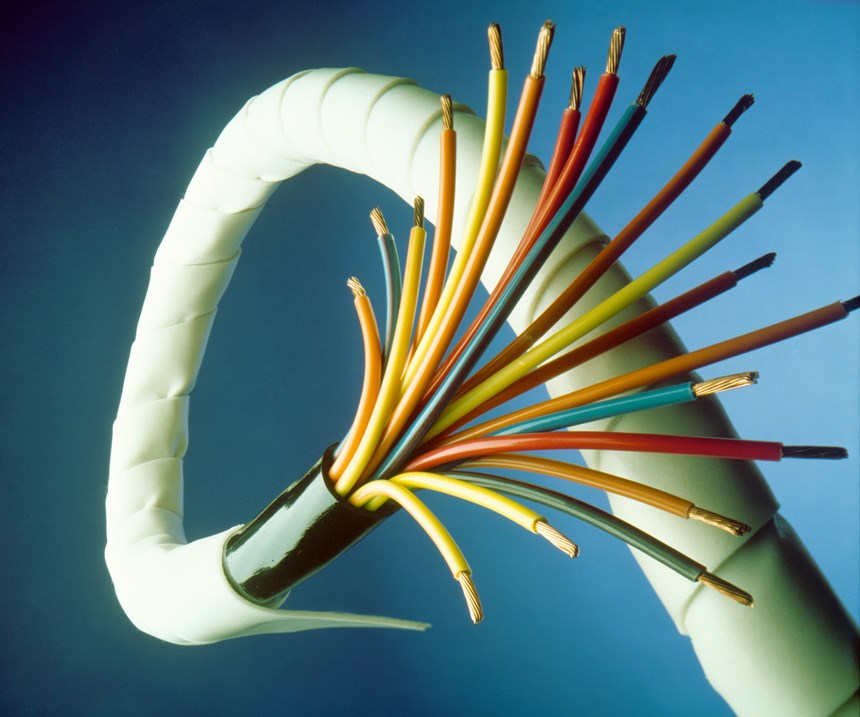

• Process aid for wire & cable: Dow Corning MB25-502 masterbatch is said to boost output by up to 25% of highly filled LDPE LLDPE, and XLPE wire and cable by decreasing extruder torque and minimizing die pressure and buildup. Introduced in early 2017, this product reportedly is more efficient than the older MB50-002 masterbatch but is still more economical than other high-performance process aids.

Related Content

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

-

Graphene Masterbatches for Flexible and Rigid Polyolefin Packaging and Beyond

Brazilian start-up Gerdau Graphene joins a growing group of graphene additives suppliers with a focus on boosting properties of large volume commodity thermoplastics.

-

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.