All-Electric Injection Molding Machine Range Expanded

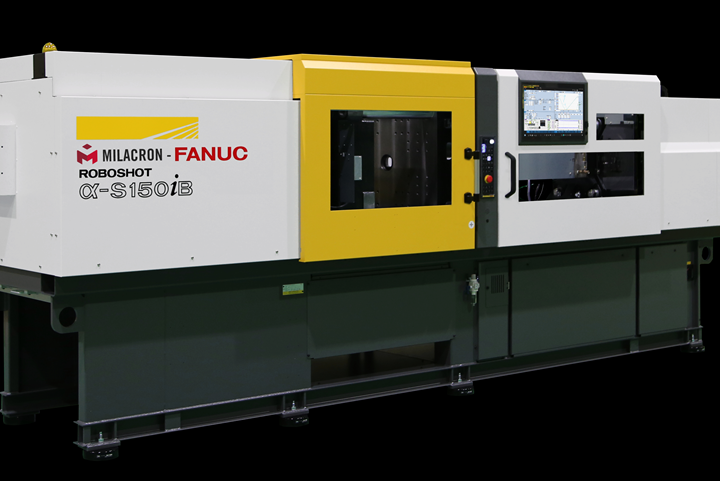

Milacron is now offering the Fanuc Roboshot Alpha-SiB, continuing Milacron’s partnership with Fanuc in the Americas and expanding on the previous Alpha-SiA series.

The Alpha-SiB will launch with five models offering clamp force of 55, 110, 140, 165 and 240 tons and featuring numerous injection capacities. The Alpha-SiB series expands the Roboshot line to include smaller injection capacity models in multiple sizes. The company said it will deliver its first Alpha S140iB to a custom molder in the Midwest in the second quarter of 2021.

Milacron said it has collaborated with Fanuc on adapting the Roboshot Alpha to tackle a wide variety of applications. This cooperation includes creating special features specifically developed for medical, LSR, optics, electrical connector and packaging applications. Among these special features is a new high-flow capacity water system that prevents operation without water flow, developed by Milacron using 3D modeling.

Milacron noted that since NPE 2018, when it showcased the machines, the company has seen great interest in integrating Mold-Masters hot runner controllers. Using Modbus and SPI communication protocols, Milacron says it has developed capabilities that can reduce human error in operation and allowing for the creation of unique shut-down sequences via Roboshot’s customized I/O feature applying ADD/OR logic.

Five models of Fanuc’s Roboshot Alpha-SiB series of all-electric injection molding machines will be made available by Milacron.

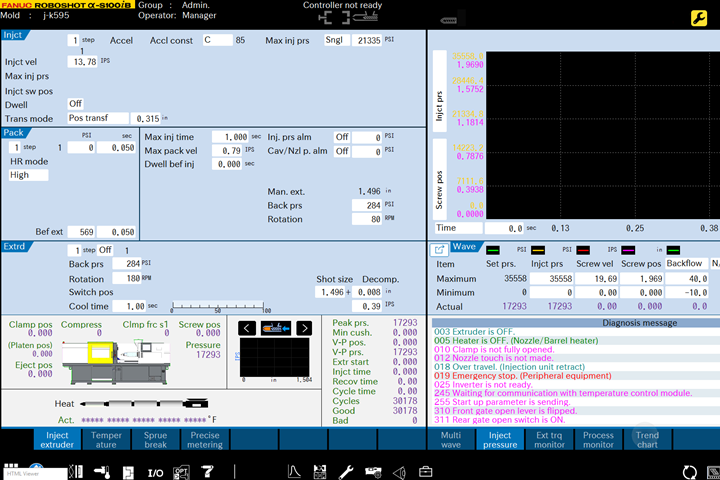

The new Alpha-SiB series includes a higher resolution and performance Panel iH control and new electrical standards. Additionally, several features that were optional are now standard. This includes increased mold stack height, three-stage air eject, expanded I/O for automation/sequencing, precision clamp force control for consistent venting and reduced mold wear, and 200 Operator IDs with custom lock-out capability for security control and tracking.

Some addition mechanical and electrical features include standard mold clamp force sensor with minimum clamp force adjustment and auto-adjust, and the removal of the jam bar and use of advanced servo drive system that meets EN201 and ANSI standards.

The standard injection pressures, velocities, screw diameters and I/Os were all increased or expanded, while the standard tie bar was also lengthened on select models. There’s also an optional high-speed ejection feature for some machine models.

On the software side, an auto start-up parameter change can reduce human errors during machine start up, and the Roboshot LINKi2 allows users to view the entire molding network from any machine. OPC-UA communications can support auxiliaries using the same protocols under the latest global standardization.

The 21.5-in. full HD control has a 1920-by-1080-pixel resolution and runs the Windows-10 IoT based platform. There are multiple USB connectivity options, including USB 3.0, as well as multiple Ethernet ports. The control offers 23 languages, can store data for up to 500 molds, and can export up to 50,000 alarm history log records, as well as 100,000 log records for last change of data and 100,000 log records for machine operation.

The Roboshot Alpha-SiB’s control offers 23 languages and can store data for up to 500 molds.

Related Content

-

Fakuma 2023: More Details on New Machine Line

Wittmann Battenfeld has released more details on the new EcoPower B8X debuting at Fakuma (October 17-21; Friedrichshafen, Germany), which it previously announced.

-

Medical Grade Injection Molding Machine Line is Cleanroom Ready

JSW America says the J100ADS-110U medical grade molding machine has been optimized to prevent dust, rust and other contaminants.

-

Word Games: What’s a ‘Hybrid’?

Any molder will tell you there’s a difference in working with electric vs. hydraulic drives. Servohydraulic is still hydraulic; a hybrid machine is something different. Imprecise use of terms causes needless confusion.

.png;maxWidth=300;quality=90)