Architectural Fabricator's Novel 3D Printing Process Used in Unique Nashville and Chicago Installations

Techmer PM designed the materials for both projects.

A novel 3D printing process developed by Branch Technology, Chattanooga, Tenn., was used in two recently completed unique projects. The firm, an architectural fabricator with a specialty in large-scale 3D printing, used compounds developed by Techmer PM for both installations—one an outdoor structure of record-breaking proportions in Nashville, Tenn., and the other an indoor hanging garden at Chicago’s Field Museum.

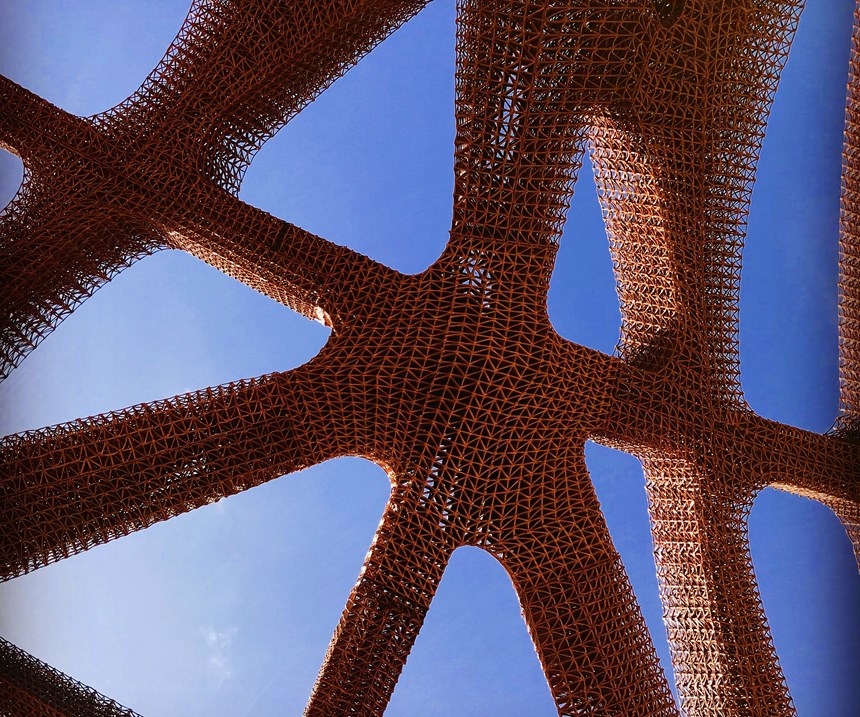

At the technology’s core, as described by Branch, is the Cellular Fabrication (C-FAB) production process, which combines industrial robotics, sophisticated algorithms, and carbon composite materials to freeform print-open cell structures. It is said to be distinctive in that it prints volumes as cellular matrices. The open-cell nature allows for efficient builds and endless dimensional form. For architectural applications, the matrix acts as a framework or scaffold to accept traditional building materials.

In these two latest projects, however, Branch applied the other version of its product—which uses only an exposed matrix. According to Branch, the matrix can be used in this manner to create structures that “are as beautiful as they are revolutionary.”

C-FAB uses a patented extrusion head attached to a Kuka Robotics arm that travels along a horizontal track creating a build volume of 3000 ft3. Specially developed algorithms allow it to translate virtually any three-dimensional design into physical form. This process creates full-scale building elements and is capable of generating components that are 8-ft-wide-by-12-ft-high-by-30-ft long. Each component can be attached to the next, allowing even larger builds and continuous forms of unprecedented scale. Here’s some more information about the two installations.

● ‘One-City’ outdoor band shell: The Nashville installation leverages the C-FAB methods of 3D printing wherein material can be solidified in mid-air to create open-matrix structures capable of taking on virtually any form. The project involved using these techniques to create a band shell that measured 42 feet in diameter and more than 19 feet tall, making it the largest free-form, 3D printed structure in North America. One City also boasts Branch’s longest unsupported span of 42 feet, creating strength through optimized geometry, without the need for structural steel.

Comprising a total of 36 smaller parts, the largest individual component measures more than 18 feet long and fills a volume of 61.5 ft3.

Techmer PM’s Electrafil, a specialty carbon-fiber-reinforced ABS, was chosen for the band shell. The large structural elements of the construction required a lightweight, high-strength material, according to Techmer PM Product Development Manager Alan Franc. “Electrafil provides the highest strength and stiffness performance available in thermoplastics compounds, and those were the most important properties for this project,” He also noted that Electrafil compounds also provide excellent 3D-printing characteristics.

● ‘Nature Clouds’ hanging gardens: The installation at the Chicago Field Museum of Natural History reportedly represents the world’s first and largest free-form 3D-printed hanging garden produced for the museum’s 125th anniversary. The project’s goal is to bring a missing natural living element in the form of an ever-evolving “living reef” or the museum’s Stanley Field Hall.

The four hanging gardens, or clouds, comprise 3940 lb of printed material and steel, and support vegetation, hydroponics, lighting, theatrical fog and sound equipment with a combined weight of 12,270 lb. Each cloud can be raised or lowered as needed. The largest of the four also provides an immersive plant environment when lowered for pubic interaction.

Techmer PM confirmed the material used is a specially formulated biopolymer compound, created specifically to meet the museum’s requirements for strength, flammability, and bio-sourced resin, according to Techmer PM’s Franc. The project’s designer, Daniel Pouzet, and the museum’s exhibits group chose Branch’s C-FAB method to leverage the technology’s strength, light weight, design freedom and, cost effectiveness compared with traditional steel construction.

C-FAB’s strength-to-weight benefits helped make this material the clear choice for the installation’s interaction with the Field’s historic plaster ceiling structure, according to Branch. The project’s total printed volume amounts to 756-ft3, comprising 279 total parts. The project was created as a kit of repeating parts capable of supporting more than 1000 plants and plant-life systems. “Typical construction methods are constraining… custom complex form is prohibitively expensive and often inconceivable to manufacture. With C-FAB, cost-effective design freedom is democratized for all,” said Branch Technology founder and CEP Platt Boyd.

Related Content

Freeform Injection Molding Eases the Path to Medical Device Product Testing

A development and manufacturing service provider is using dissolvable molds to build injection molded silicone prototypes.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreKraussMaffei Launches Two Additive Manufacturing Lines at K 2022

Long established in injection molding, extrusion and polyurethane reaction process machinery, 184-yr-old KraussMaffei prepares to enter the industrial additive manufacturing market.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read More