Automation: Top Rollers Feature Advanced Sensors

ROEQ’s GuardCom systems uses sensors to instantly communicate with stationary conveyors moving goods on and off the mobile robot topped by a conveyor.

ROEQ, a Danish manufacturer of mobile robotic equipment distributed in the U.S. by Hartfiel Automation (Eden Prairie, Minn.), has launched the GuardCom line of top rollers—conveyors on top of mobile robots. Unlike existing top rollers that connect with stationary conveyors via WiFi, GuardCom uses sensors for instant communication.

GuardCom includes a physical guard that rises to prevent packages from rolling off.

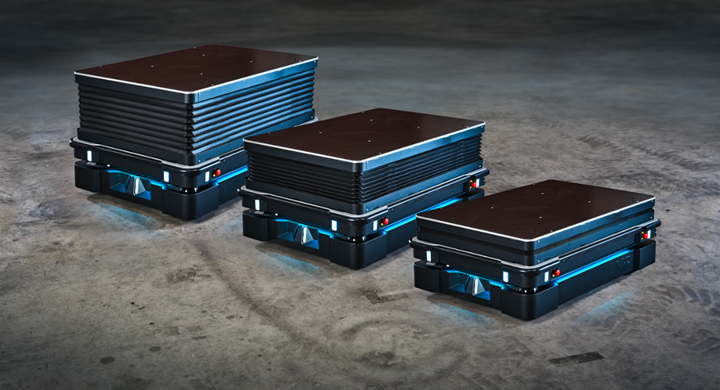

The company is also releasing top rollers with adjustable height for Mobile Industrial Robots (MiR; Odense, Denmark) models, MiR250, MiR500 and MiR1000. ROEQ notes that WiFi instability is a common workplace challenge, and in material handling applications with devices passing data around between mobile robots, third party receiving stations and conveyors, an network interruption can cause costly errors and downtime.

ROEQ’s technology consists of two products; GuardCom installed on the stationary conveyor station, and GuardCom Connect installed on the autonomous mobile robot. In operation, multiple GuardCom Connects can work with the same GuardCom and vice versa. GuardCom is compatible with all stationary conveyor stations, replacing third party wireless devices.

GuardCom uses sensors for instant communication.

Once the mobile robot has arrived at the conveyor, GuardCom signals to the stationary conveyor station that the robot is ready to receive or deliver the packages. That same signal is simultaneously sent to the robot letting it know that the stationary conveyor is ready. Once the transfer task is completed, both units receive a signal that it is safe for the robot to leave.

GuardCom integrates into the stationary system via cabled connections, and the handshake process between the GuardCom and the mobile robot is wireless. To further prevent misplaced or dangling packages, GuardCom includes a physical guard that rises to prevent packages from rolling off. An alarm alerts the operator to come onsite to remedy the situation, or for the conveyor to roll backwards automatically.

ROEQ also introduced the new ROEQ TR500 Auto and TR1000 Auto top roller modules with automatic lifting mechanisms, enabling MiR’s largest robots, the MiR500 and MiR1000 (with 1100 and 2200lbs payload respectively) to pick up and deliver goods at varying heights in the factories without human intervention. They’re able to automatically adjust in a height range of 19.7 to 31.5 in. (stroke is 9.8 in. ) from floor to rollers.

ROEQ’s auto top roller modules feature automatic lifting mechanisms.

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

Automation Evolution: From Robots to Work Cells, Solo Devices to Integrated Systems

Injection molding automation has progressed from devices to systems, from simplicity to more complex capabilities. The author traces this development through various levels of automation – all still available choices today – and analyzes the costs and capabilities for each level.

-

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.