Blending: 'Smart' Software Saves Labor Costs, Boosts Quality

Helps operators make blending decisions and reduce errors when manually adjusting recipes.

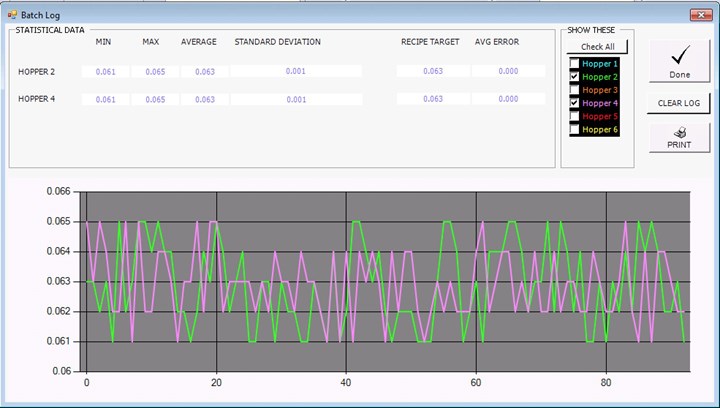

BlendTrac is AEC’s new software program for data automation of gravimetric blenders. It collects useful data to help processors centralize inventory control, optimize quality and reduce labor and material costs. BlendTrac aggregates and presents blending data in a way that reportedly helps operators make well-informed decisions and reduce errors.

BlendTrac brings inventory monitoring to a central computer system while adding additional data monitoring to optimize quality and reduce expenses. BlendTrac can look at multiple blenders within a facility or even machines all over the country, offering processors an easier, more efficient way to manage inventory.

BlendTrac is designed to help aggregate and present the data in a way that helps operators make blending decisions and reduce errors when manually adjusting recipes. Compatible with Windows 10, this software can monitor and control up to 100 A-B BD and OA Batch Weigh Blenders. It can also log up to 1000 alarms per blender and up to 5000 consecutive batch weights. it stores an infinite number of recipes and offers the ability to download recipes to blenders from the recipe book. Additionally, it can automatically generate time and date stamped reports on an hourly basis and track material reference numbers as well as lot numbers and silo numbers. This can help link material usage and specific jobs if a quality issue arises with a certain resin lot.

Operators can utilize BlendTrac to reduce part costs by reducing the use of expensive additives. For example, a job may specify a 4% setpoint of additive with a 1% allowed tolerance. With the information BlendTrac provides, operators can adjust the process and stay close to the low tolerance limit of 3%, reducing expensive additive usage.

BlendTrac can be added to new AEC Batch Weigh Blenders or installed with older versions.

Related Content

-

Cone Tumble Blender Utilizes Diffusion Mixing

Delivers low impact, highly accurate, and repeatable mixing of powders, granules, pellets, and other free-flowing solids.

-

Loaders, Blenders Made Specifically for Medical Processors

NPE2024: FDA-compliant auxiliaries suited for injection, extrusion, blow molding.

-

Finding Efficiencies in How Components Work Together

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

(2).jpg;maxWidth=970;quality=90)

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)