Blow and Fill a Bottle Simultaneously: Learn More at NPE2018

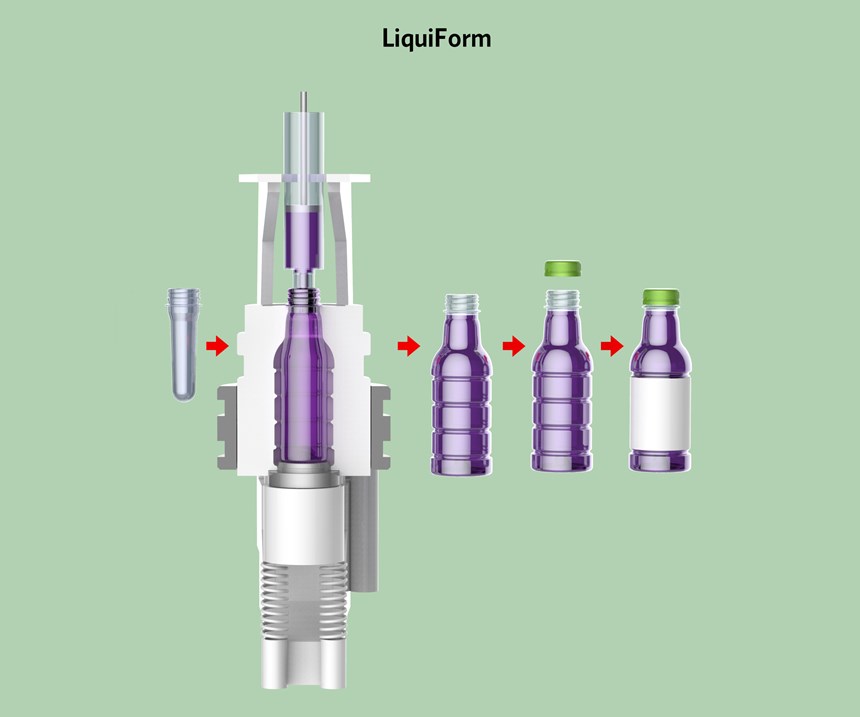

Unique technology for blowing a plastic bottle with the liquid contents instead of air is being highlighted at NPE2018 this week.

The Liquiform Group, a division of Amcor, based in Saline, Mich., is discussing the latest capabilities of the technology, as well as the first commercial application. In Booth S16078, Liquiform Group will show samples of containers from 200 ml to 1 gal, made from PET, HDPE, and PP on a lab machine in Saline. These containers were formed using different types of liquids—water, tea, soap, shampoo, detergent, cleaners, and conditioners—in a range of viscosities from 1 to 10,000 cP. Liquiform has also formed containers with contents at temperatures from 10 C/40 F to 87 C/188.6 F.

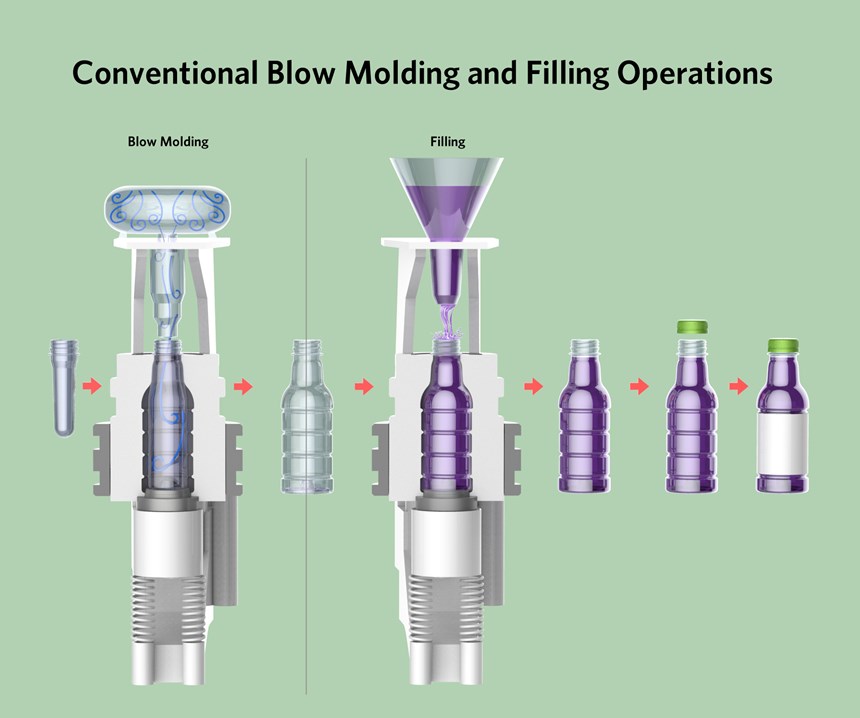

Liquiform technology combines blowing and filling in a single step, eliminating the need to transport and store empty bottles. Similar to two-stage stretch-blow molding, it starts with reheating an injection molded preform. Eliminating compressed air saves on energy, floorspace, equipment and maintenance costs. In addition, containers formed with incompressible liquids (like aqueous fluids) have demonstrated superior package definition and material distribution versus containers blown with air.

The first commercial application is a 12-oz PET bottle for Nature’s Promise hand soap (photo) from Greenblendz of Auburn Hills, Mich. It was made on a proprietary machine built by Amcor for its own use. Licensees working to develop Liquiform technology and markets include other machine producers—KHS, Krones, and Sidel—as well as Yoshino Kogyo, Japan’s largest bottle maker.

Related Content

-

Reversing Logistics for Plastic Film Recycling

Learn how Mainetti built a circular supply chain for clear film packaging.

-

Pregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

.png;maxWidth=300;quality=90)