Blow Molding: Enhanced PET Stretch-Blow Machine And New Leak Tester

All-electric reheat stretch-blow machine offers new features for custom blow molders. Enhanced leak tester handles small to large containers.

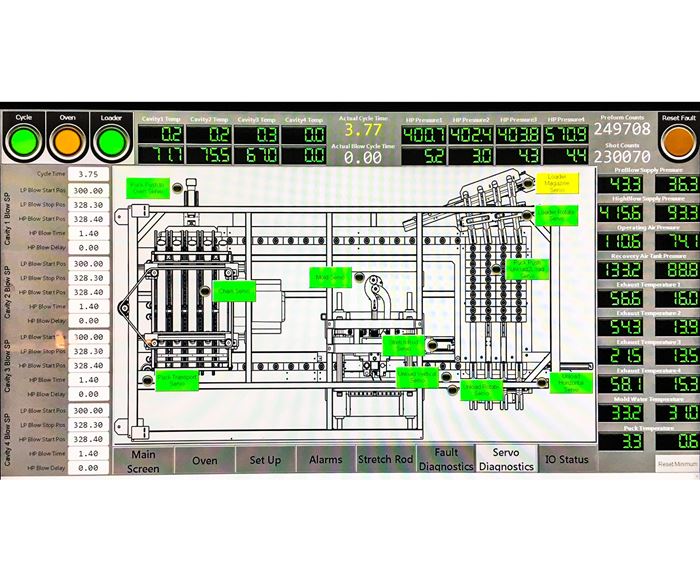

At NPE2018 next month, W. Amsler Equipment Inc., Richmond Hill, Ont., will introduce the next generation of its linear stretch-blow molder as well as a newly enhanced leak tester. The L42X all-electric reheat machine offers several new features for custom PET blow molders, including preferential heating, neck orientation, and hot-fill capability. It can make up to 2 L containers at up to 6500/hr in four cavities. It can also run two-cavity molds for containers up to 5 L. Neck finishes range from 18 to 70 mm.

The L42X has a 40-ton clamp and four parallel heating ovens, one for each cavity. It is equipped with 12 Bosch Rexroth servo motors, compared with three servos for the previous model. The extra motors are said to provide more repeatability and lower energy consumption, while requiring less wiring, which results in easier troubleshooting.

Other key features include agitated preform infeed to prevent bridging, preform temperature sensing prior to blow, pre-blow flow control for each cavity, water-cooled neck shields, and a large Windows-based touchscreen with access to assembly drawings, bills of materials, setup guides, troubleshooting, and training videos.

The company is showing its newly enhanced leak tester that inspects bottles from 10 ml to 20 L at up to 18,000 bph. Equipped with a camera system that can detect neck ovality issues, the leak tester can find holes as small as 0.006 in. and can check for obstructions in the bottle neck and variations in wall thickness. Other optional features include detecting color deviation, batch counting, and fallen bottle detection.

Amsler is also showing its stand-alone spin trimmer for both stretch- and extrusion-blown containers of PET, PETG, HDPE, PVC, and PP. It handles container diameters up to 200 mm at up to 6000/hr.

Related Content

-

Understanding the ‘Science’ of Color

And as with all sciences, there are fundamentals that must be considered to do color right. Here’s a helpful start.

-

As Currier Grows in Medical Consumables, Blow Molding Is Its ‘Foot in the Door’

Currier Plastics has added substantial capacity recently in both injection and blow molding for medical/pharmaceutical products, including several machines to occupy a new, large clean room.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.