Blow Molding: Online PET Preform Inspection Uses AI to ‘Self-Learn’

SACMI’s new Preform Vision System can be used inline with PET preform injection molding.

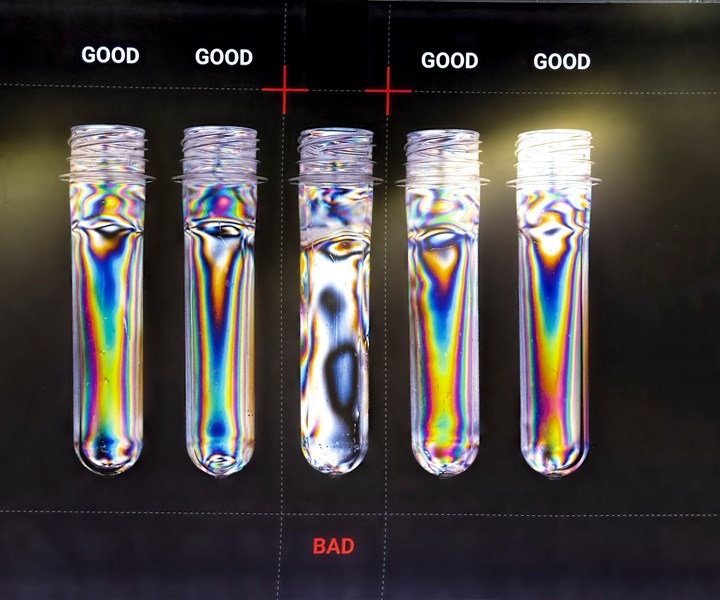

At the recent K 2019 show in Düsseldorf, SACMI of Italy showed off a new version of its Preform Vision System, PVS10L. Designed for use either offline or in line with the company’s IPS preform injection molding system, PVS10L uses polarized light and seven to 12 cameras to check PET bottle preforms for stresses, deformation, black specks, color, haze, crystallinity, and dimensions of the body, neck and gate. It also reads the cavity number so that defects can be associated with a particular cavity and preforms from that cavity can be segregated as rejects. According to SACMI, it was not previously possible to use polarized light to evaluate stresses in an in-line setup because existing alogorithms were not up to the task. SACMI says it has now replaced offline sampling checks performed manually at test benches with a fully automated system that can inspect 36,000 preforms/hr. What’s more, this system uses artificial intelligence (AI) to “self-learn” all the required QC checks. One result is that the system can change over to a preform with different length, diameter and color in 1 min.

SACMI’s newest Preform Vision System uses polarized light for online 100% inspection of stresses in PET preforms.

SACMI also has a new version of its Bottle Vision System (BVS) for complete inspection of blown bottles of various resin types. It uses higher resolution cameras and faster data processing to check the bottle top seal, neck finish, sidewall and bottom.

Related Content

-

A Simpler Way to Calculate Shot Size vs. Barrel Capacity

Let’s take another look at this seemingly dull but oh-so-crucial topic.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

How to Get Rid of Bubbles in Injection Molding

First find out if they are the result of trapped gas or a vacuum void. Then follow these steps to get rid of them.