Bottle-To-Bag Technology For Making Woven-Tape FIBCs From rPET

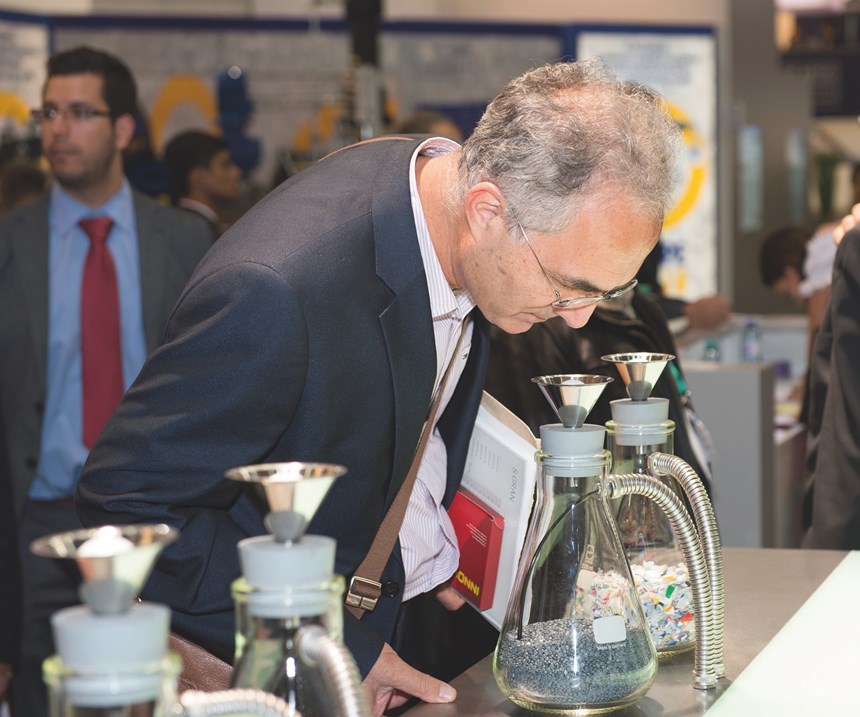

Starlinger is exhibiting an rPET FIBC at Booth W6885 along with a “smelling table” that highlights “smell-improved” regranulate.

New technology developed by Austrian-based manufacturer Starlinger & Co. GmbH (U.S. office is American Starlinger-Sahm, Fountain Inn, S.C.) can produce woven tape fabric directly from PET bottle flakes. With Starlinger’s “bottle to bag” technology, woven bags are made directly from recycled material, and these bags are in turn recyclable. Starlinger says no virgin material is needed in the production process. Current applications are big bags/FIBCs (Flexible Intermediate Bulk Containers) for storing bulk materials and rPET PP*STAR pinch bottom bags for packaging products such as dry pet food, fertilizer, sugar, flour or rice. At NPE, Starlinger is exhibiting an rPET FIBC at Booth W6885.

Starlinger is also highlighting its odor reduction technology that reportedly produces a “smell-improved” regranulate that can be used in a wide range of applications. The three-step procedure (material preparation, degassing and post-treatment) eliminates even deeply embedded odors, according to the company. The method works without additives. At NPE2018, a “smelling table” with smelling stations allows booth visitors to smell the difference between input material and smell-improved regranulate.

Related Content

-

Looking to Run PCR on a Single Screw? Here’s What to Keep in Mind

Just drop it in and mix it up? Sorry, there’s a lot more to it than that. Here is some of what you need to consider.

-

Recycling: What's Ahead in Advanced Sorting Technology

As the industry tries to ramp up recycling, there are several innovative sorting solutions in the offing—ranging from enhanced optical sorting technologies and chemical tracers to advanced solutions based digital watermarks and artificial intelligence.

-

Revalyu Breaks Ground on PET Recycling Facility in Georgia

Company expects new facility will be capable of chemically recycling 200 million pounds of post consumer PET per year.