Enhanced Plastics Laser Welding System

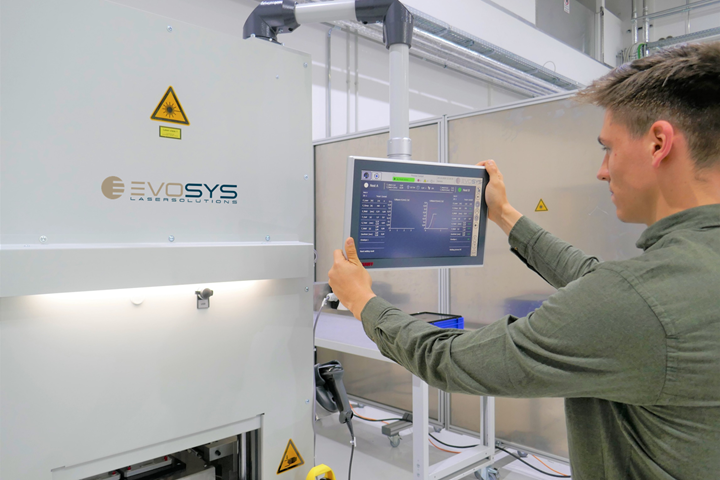

Evosy’s Next Generation HMI laser welding system offers intuitive visulaization and simplified operation.

An enhanced plastics laser welding system from Germany’s Evosys (U.S. office in Auburn Hills, Mich.) is said to feature intuitive visualization and simplification of the operation of the laser welding process, including its mechanical movements. The enhancement of the Next Generation HMI system is said to be functional independent of the control system used and offers the possibility to be adapted to growing requirements by smart additional modules.

A central overview is provided by three cockpits, which provide operators with information tailored to their area of activity—process, production and statistics - process, production and statistics. All other subpages are grouped together in function groups, with the header on each page having the same structure. This shows basic information about the machine, such as operating mode, information, warning or fault messages, as well as the current time and the current unique window number. Basic navigation is carried out via the sidebar on the right-hand side, which contains the corresponding operating elements.

The new HMI also handles the visualization and evaluation of the process data, which eliminates the need for additional hardware. The central cockpit displays all process-relevant information about the currently processed assembly. In addition, the last data records can be compared in the history of the HMI. A statistics page uses various counters to record order and production quantities and determines quality parameters. These are then displayed graphically.

The HMI is also used to store recipe data sets, export and import envelopes, create them and other system functions. For example, the monitoring of the hard disk capacity or the display of a USB camera can be integrated. The system can thus be operated with different machine controllers such as Beckhoff or Siemens, which are not visible to the end user. This does not change the functionality and above all the operation of the machine.

Related Content

-

Ultrashort Pulse Laser Marking System for Medical Devices and More

FOBA’s F.0100-ir creates deep black markings on medical plastics, stainless steel and titanium.

-

Advanced Inspection of Bottles and Labels

NPE2024: Intravis shows new system for full label inspection on round, randomly oriented bottles; and redesigned bottle inspection system with more modular design.

-

Cobot Palletizing System for Bottles

NPE2024: Proco Machinery’s new collaborative robot system palletizes bottles with trays and tier sheets up to 104 in. high.