Reciprocating Head Enables Profile-Shape Changes 'On the Fly'

NPE2024: Device eliminates the need to change tools to accommodate different profile shapes and eliminates assembly of the finished profile.

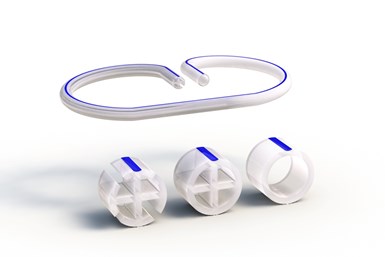

On the new reciprocating head developed by Guill Tool, the typical tip and die assembly is replaced with a linear reciprocating assembly that changes the tube’s profile on the fly within a given length. This process is repeated throughout a single extrusion run without interruptions. As a result, only one extrusion run is needed to produce a finished product, as opposed to multiple runs requiring tooling changes and manual assembly operation to connect different tubing shapes. Guill’s new reciprocating head also eliminates in-process inventory.

Source: Guill

This means there is no need for storage of various tubing shapes and connectors needed for assembly, fulfillment of orders and replenishment of finished goods.

Moreover, the reciprocating head eliminates a connecting piece, enables JIT production and products made-to-order, and reduces total run time from receiving the order to shipping, according to Guill.

Related Content

-

Belling Machine Forms 'Rieber' Socket in PVC-O Pipe

Italy’s SICA has developed an innovative Rieber belling process specific for PVC-O pipes. At the same operating pressure, these pipes require a wall thickness of about 35-40% less than those in conventional PVC pipe and allow the construction of water supply pipes up to 25 bar of operating pressure.

-

Green’s the Theme in Extrusion/Compounding

The drive toward circular economy is requiring processors to make more use of PCR. Machine builders at K—across all extrusion processes—will be highlighting innovations to help them do just that.

-

Is Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.