Honeycomb Materials Applied in Industrial Packaging and Commercial Transportation Products

EconCore’s technology for the continuous production of thermoplastic honeycomb core panels is now in mass markets.

Several commercial applications in both packaging and transportation have emerged over the last year or so which utilize the ThermHex technology from Belgium’s EconCore. In March, I blogged about the extended capabilities of the technology to produce continuous honeycombs from several high-performance thermoplastics. This was followed up with a blog on the company’s partnering with Holland’s MEAF Machines to develop and install a fully-functional laboratory-scale extrusion and forming line at the company’s recently-refurbished R&D facilities in Leuven, Belgium.

At the heart of the line is a purpose-built 50-mm extruder equipped with a special 500-mm sheet die built by Austrian flat-die specialist EMO Extrusion Molding. EconCore’s patented ThermHex technology produces honeycomb structures from a single continuous thermoplastic sheet. This involves a sequence of thermoforming, folding and bonding operations. Cell size, density and thickness of the honeycombs can be altered with simple hardware and/or process parameter adjustments. The process allows for inline bonding of solid skins to one or both sides of the honeycomb, to create an extremely cost-effective finished composite panel.

EconCore already has licensees around the world producing continuous honeycombs and honeycomb-cored laminates in polyolefins—predominantly polypropylene. The new line is allowing the company to both focus on refining the process technology for these materials and extending the potential of ThermHex by enabling it to be used with thermoplastics with superior mechanical and thermal performance. With this purpose-designed extruder, they have so far managed to obtain excellent results on around 10 different kinds of polymers.

The advantage of being able to produce core materials with optimized performance-to-weight ratios, at high speeds, in high volumes, and with the lowest possible costs, has brought the honeycomb structures—once reserved for aerospace and low-volume, less cost-sensitive domains—to mass markets. The early breakthroughs for EconCore’s technology were in packaging.

Japan’s Gifu Plastics, the company’s first licensee in the packaging arena, focused on lightweight, high-performance solutions made with PP honeycomb-cored sandwich panels. Over time, the technology’s advantages have attracted many more new users focusing on packaging—and other sectors as well—with EconCore’s licensing footprint now also including automotive, transportation, building and construction, and PP core materials for composites.

The company confirms that packaging is still the cornerstone of its licensing business, with the largest share of licensing dedicated to applications in this sector. At the same time, the versatility of being able to connect the steps of first making the honeycomb core with in-line bonding of metal skins to make lightweight and stiff sandwich panels is making this technology appear in an increasing range of transportation applications. For truck trailers and truck bodies, for example, the potential for weight reduction is compelling with honeycomb core material being up to 90% lighter than incumbent solid cores. As a result, leaders in commercial transportation in North America and Europe are adopting the ThermHex technology. Take a look at some of the interesting applications in packaging and transportation that have become a reality.

Industrial Packaging

● Japan’s Gifu Plastics, which has invested in a second production line to meet the market demand, has developed a variety of sleeve boxes to meet specific customer needs. These include boxes with four-side opening and closing, sleeve boxes with a transparent view section integrated into the packaging, and boxes with aluminum frames for exceptionally heavy goods.

The company is also expanding into other industrial packaging/logistics solutions, such as lightweight washable pallets with honeycomb core materials, and layer pads for protection of goods during transport and for in-plant material handling. Gifu also has a range of foldable storage and delivery boxes of various dimensions; components for carry-carts; container covers and even partition walls for logistics facilities.

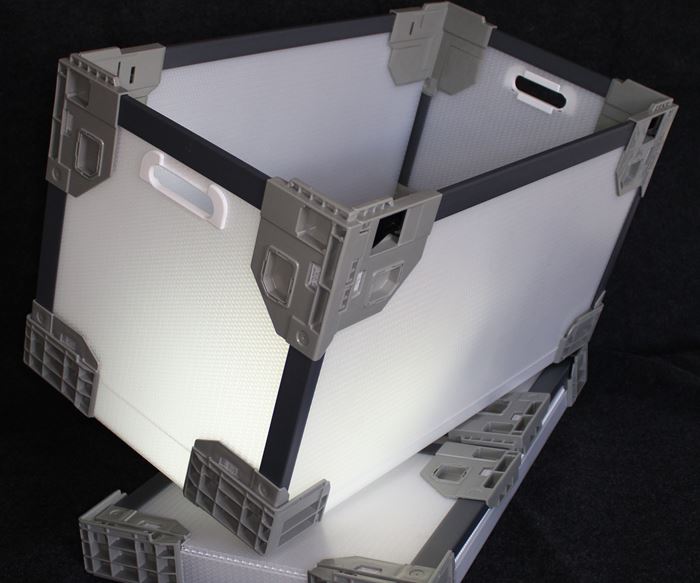

● Italy’s Karton, a recognized leader in thermoplastic packaging, used ThermHex technology to produce industrial packaging products that are said to be setting a new standard in performance. Honeycomb core sandwich panels made by Karton are used for sleeve packs in collapsible reusable packaging systems that significantly outperform alternatives. By combining its expertise in packaging with the technology to produce true honeycomb structured materials, Karton is delivering a world-leading solution that benefits the use of reusable packaging solutions with high performance per unit weight and the potential to increase reuse cycles, according EconCore.

Karton is also developing solutions for automotive component logistics with heavy-duty layer pads to protect delicate and costly automotive components during transport.

● Turkey’s Roplast has focused largely on developing business for automotive interior cladding applications since installing the honeycomb panel production line. It recently took a major step forward by extending its offering to include reusable industrial packaging. Its HexaPak reusable packaging system is taking the Turkish market by storm, according to EconCore, especially for intra-and inter-site logistics customers in Turkey. These foldable containers collapse to take up to 80% less volume—making them ideal in the reusable industrial packaging cycle where goods are loaded and transported, with empty containers than either being refilled to continue their path in the logistics chain, or collapsed and returned to the source location for reuse.

Commercial Transportation

● U.K.’s Tata Steel, led the way of combining thermoplastic honeycomb core materials with metal skins using the ThermHex process. It produces its Coretinium composite using the technology which combines in-situ PP honeycomb cores with their Colorcoat Prisma pre-finished steel skins. The breakthrough in rigidity-to-weight performance is delivering substantial value to Tata’s commercial transportation customers. One notable example is Cartwright’s new Streetwise Urban Delivery Trailer, deployed in U.K. cities, a half-ton lighter than before thanks to Tata Steel’s Coretinium.

● In North America, the number one in commercial transportation company Wabash National, Lafayette, Indiana, has long been a leader in composite innovation with DuraPlate, introduced over 20 years ago. Early this year, Wabash showcased its new DuraPlate honeycomb core panels produced with ThermHex. For truck bodies, the opportunity is clear, these panels are engineered to provide optimal weight-to-performance for their final-mile applications. The honeycomb core panels are 22% lighter than solid-core composite panels, and for truck bodies the lighter panels are said to be more durable than current products. The adoption of honeycomb technology for truck bodies is building momentum this year and significant manufacturing capacity is in the works for 2019.

Related Content

Recycled Material Prices Show Stability Heading into 2023

After summer's steep drop, most prices leveled off in the second half.

Read MorePrices of All Five Commodity Resins Drop

Factors include slowed demand, more than ample supplier inventories, and lower feedstock costs.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreFundamentals of Polyethylene – Part 5: Metallocenes

How the development of new catalysts—notably metallocenes—paved the way for the development of material grades never before possible.

Read MoreRead Next

Processor Turns to AI to Help Keep Machines Humming

At captive processor McConkey, a new generation of artificial intelligence models, highlighted by ChatGPT, is helping it wade through the shortage of skilled labor and keep its production lines churning out good parts.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More

.png;maxWidth=300;quality=90)