Injection Molding: Simulation Factors in Material Compression and Machine Response During Injection

Moldex3D version R17 increases prediction of filling speeds and pressures.

The latest version of Moldex3D injection molding simulation from CoreTech System in Taiwan includes two factors intended to increase the accuracy of mold-filling predictions. First, Moldex3D R17, released last year, takes into account the compressibility of the melt during screw recovery and injection. Since the melt acts somewhat like a spring, disregarding this factor will result in a gap between the simulated and actual flow rates through the nozzle, runner and mold.

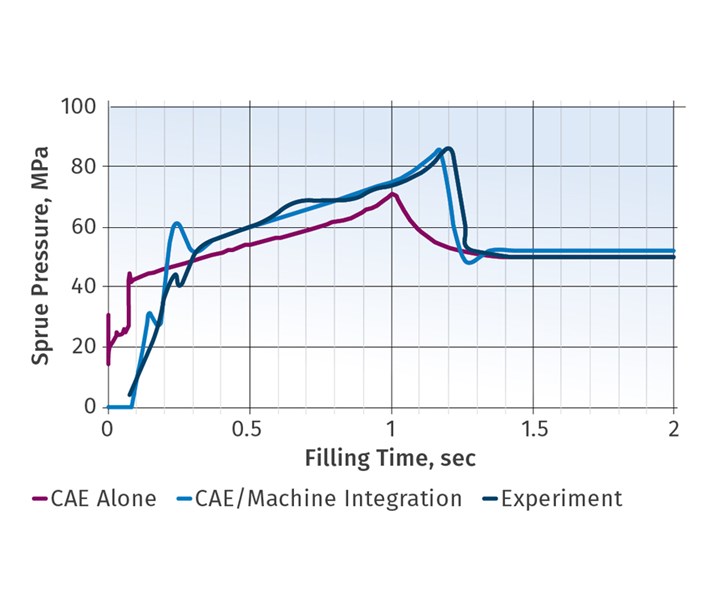

Including material compression and machine response in Moldex3D simulation provides a closer match to experimental results than conventional simulation without those two factors.

Second, conventional CAE predicts melt flow through the tooling based on settings for injection speeds, without considering the machine response—i.e., the response speed of the control loop to attempt to satisfy the speed settings throughout the injection profile. CoreTech offers instructions on how to set up and conduct experiments to quantify the machine response, and the new version of Moldex3D lets users set the filling speed and pressure response as part of the simulation parameters.

The accompanying graph shows the difference in simulation based on standard CAE inputs alone vs. the results of actual experiments and Moldex3D with melt compression and machine response (“machine integration”) included.

Related Content

-

Injection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.

-

How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.