Injection Molding: Small Electric Press Debuts In LSR Micromolding

KraussMaffei adds 25-ton model to all-electric PX series of injection molding machines. First demonstrated in LSR micromolding. KM also introduces solid silicone feeder for bubble-free parts.

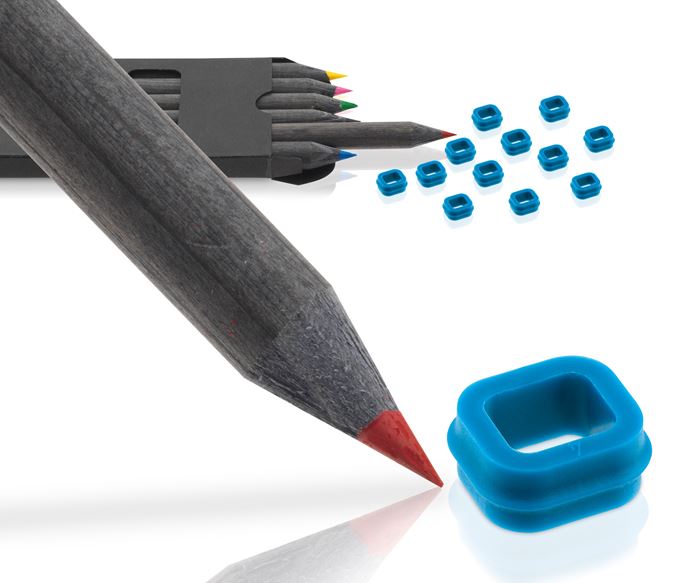

At its recent Competence Forum open house in Germany, KraussMaffei (U.S. office in Florence, Ky.) showed off the newest and smallest member of the highly modular, all-electric PX series of injection presses. The new PX 25 has 25 metric-ton clamp force; the rest of the line ranges from 50 to 200 m.t. It was demonstrated in an LSR micromolding application—a radial seal (pictured) with an intricate undercut and weighing 0.15 g.

For this project, the press was equipped with a new injection unit housing a 12-mm screw. Cycle time was 14 sec.

Addressing growing demand for both LSR and solid silicones in the U.S. and Asia, KM also introduced the new AZ 50 feeder for solid silicone rubber on a servo-hydraulic CX 200 two-platen press (pictured). The feeder has a rotating hopper and pulls the silicone downward using a continuously rotating stuffer screw. Rear ventilation allows air to escape upwards, unlike other systems that use a piston, which is more likely to result in entrapped air and bubbles in molded parts, KM says.

Related Content

-

Datwyler Expands O-Ring Production

The company has added injection molding machines to production sites in Mexico and China to boost production.

-

Beacon MedTech Solutions Names New President

The Massachusetts-based medical molder and contract manufacturer has appointed industry veteran Jim Colony.

-

Custom Molder Manages Growth on Several Fronts

Adding people, plants and machines, expanding capabilities in LSR, high-tonnage presses, automation and 3D printing—EVCO Plastics maintains momentum through challenging times.