Injection Molding: Updated Mold-Filling Analysis Is 30% Faster

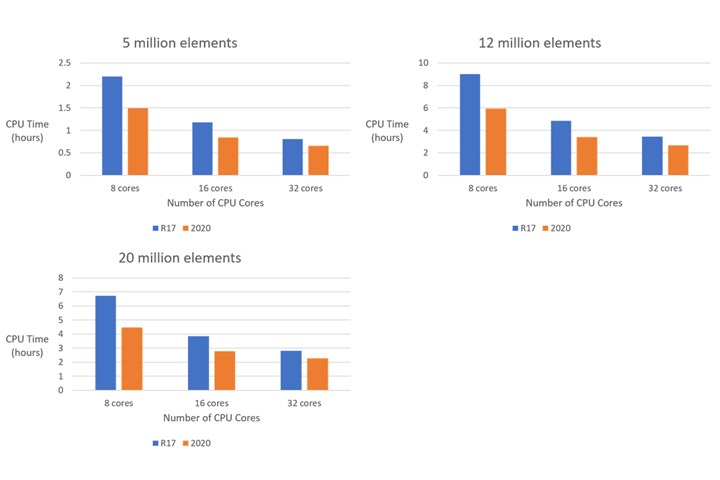

Coretech System of Taiwan says its new Moldex3D 2020 solver averages 30% faster calculations than the preceding R17 version with the same computing hardware.

Share

Read Next

Coretech System of Taiwan says its new Moldex3D 2020 solver averages 30% faster calculations than the preceding R17 version with the same computing hardware. The latest release of the mold analysis software was tested on different high-performance computing platforms with eight, 16 and 32 cores and on mesh models with 5 million, 12 million and 20 million elements. One example is shown here.

Comparison of filling-analysis time between Moldex3D 2020 and R17, using an AMD EPYC 7302 processor.

Related Content

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

-

Where and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

-

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.