Laser Welder for Small, Delicate Plastics Parts

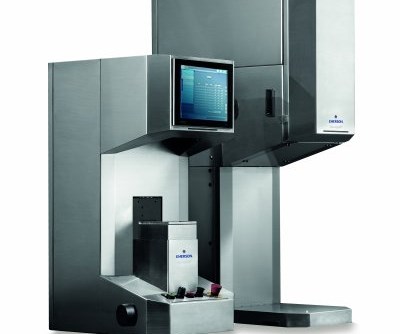

Emerson’s Branson GLX Micro laser welder targeted to delicate parts used in medical, consumer and electronic industries.

A laser welder specially designed for small, more delicate parts used in the medical, consumer and electronics industries has been launched by Emerson, Danbury, Conn., the company’s latest addition to its Branson line of welders.

New Branson GLX Micro is said to provide precise, clean and repeatable welds of delicate and intricate components. The benchtop version of the GLX Series uses advanced laser technology and incredibly low clamp force to produce welds of superior aesthetic quality and performance. This reportedly provides manufacturers with greater design freedom and increased production throughput.

The GLX Micro uses the patented Simultaneous Through-Transmission Infrared (STTlr) laser welding technology which reportedly which enables manufacturers to achieve superior weld strength and quality with exceptional speed and flexibility. With STTIr, all lasers are fired simultaneously to heat, melt and bond the component parts along the entire weld surface in 0.5 to 5 seconds, depending on material and geometric complexity.

This method is said to be highly repeatable and stable, helping to increase production throughput. STTlr eliminates the use of friction which may generate flash and particulates, thereby ensuring smooth and barely visible weld lines can be incorporated into product designs. With STTlr, highly complex 3D contours can be accommodated, allowing designers to create parts for maximum functionality and ergonomic appeal.

The GLX-micro offers the industry’s lowest clamp force of 1 Newton, enabling the joining of small and very delicate parts, including those with embedded electronics and sensors. The unit is cleanroom compatible, having a stainless-steel design, requiring no lubricants, and being powered from a remote electrical cabinet that can be positioned outside the production area. To support traceability, production data, including weld depth and clamp force, is available in a range of formats and can be outputted to the manufacturing execution system.

Related Content

-

Can Plastic Recyclates be Welded Ultrasonically?

What is possible with ultrasound? Will the result with recycled plastics material actually be worse than with standard material? Do we have to adapt our technology?

-

Stratasys to Acquire Covestro’s Additive Manufacturing Materials Business

This acquisition will result in Stratasys having an expanded portfolio of differentiated materials in stereolithography, DLP, and powders.

-

Hot Wash Systems for Recycling Polyolefins

Herbold can configure wash plants for polyolefins that can produce high-quality, food-grade recyclates.

.png;maxWidth=300;quality=90)