Light-Duffusing Color and Additive Masterbatches for LED Light Sources

Tosaf’s new LD masterbatches said to create uniform diffused light on backlit surfaces.

Many LED light sources have a problem in creating uniform diffused light, resulting in brightness concentrations –or, so-called "hot spots", on backlit surfaces. New light-diffusing (LD) color and additive masterbatches from Tosaf Color Services (U.S. office in Bessemer City, N.C.. have been shown to effectively prevent this undesirable phenomenon.

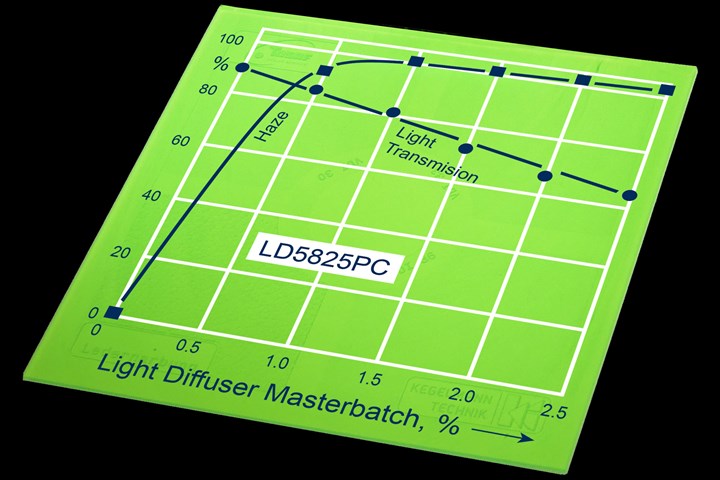

In extensive laboratory trials, the micro-fillers these masterbatches contain were optimized with regard to material, refractive index, transparency, geometry and dimensions. As a result, only very small amounts of masterbatch--1% to 2 % , are needed to effectively scatter the light in originally transparent material, predominantly PMMA and PC. At the same time, the light transmission and mechanical properties of the base material are largely retained. In addition to color-neutral grades, combinations with specific colorings and other functional properties such as UV stabilizers are available.

The use of such LD masterbatches gives extrusion and injection molding companies maximum flexibility without the need to keep diverse stocks. It means that they are able to adjust the targeted light scattering properties for the respective application and material thickness merely by varying the quantity added. Additionally, they have the possibility to produce the corresponding mixture either before filling it into the hopper, or to add the masterbatch inline to the melt. Another advantage is derived from using masterbatches generally, namely that although the responsibility for homogeneous dispersion passes over to the converter, this route is often more cost-efficient compared with buying ready-to-use material, especially with large volumes.

Said Tosaf product manager Rudolf Reinhart,"Producers of parts or extrudates for lighting technology are, because of the large amount of apparatus needed, not usually able to incorporate the light-scattering additive themselves. However, our easy-to-process light-diffuser masterbatches open the way for them to achieve inexpensive flexibility, because they are designed for products without streaks or other defects. This means that our customers have a cheaper alternative to compound solutions."

Added marketing manager Andreas Kruschinski, "We see a growing demand for light-scattering plastic parts. This is due not only to the increasing popularity of LED light sources, but also to the increasing range of applications. A current example is the development of evenly backlit decorative elements for interior and exterior automotive parts. Relevant applications are also foreseeable over and above lighting technology in many other areas, including white goods, furniture design and consumer electronics, for example for edgings for gaming machines.”

Related Content

-

Coke Makes Bottle Changes to Boost Recycling

Sprite bottles will be clear, while Dasani bottles will be made with recycled plastic.

-

How to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.