Materials: High-Heat Glass-Reinforced Nylon 66 Compounds Outperform Comparable Nylon 66

Teknor’s new Creamis 240H7.5 can replace costly specialty polymers like PPA.

A new series of high-heat glass-reinforced nylon 66 compounds is said to bridge the cost-performance gap between standard heat-resistant nylons and costly specialty polymers, providing injection molders with a more economical alternative for automotive and other metal-replacement parts. The Creamid 240 H7.5 Series from Teknor Apex Company, Pawtucket, R.I., will be launched at Fakuma 2018 in technical talks at the company’s booth (B2-2114).

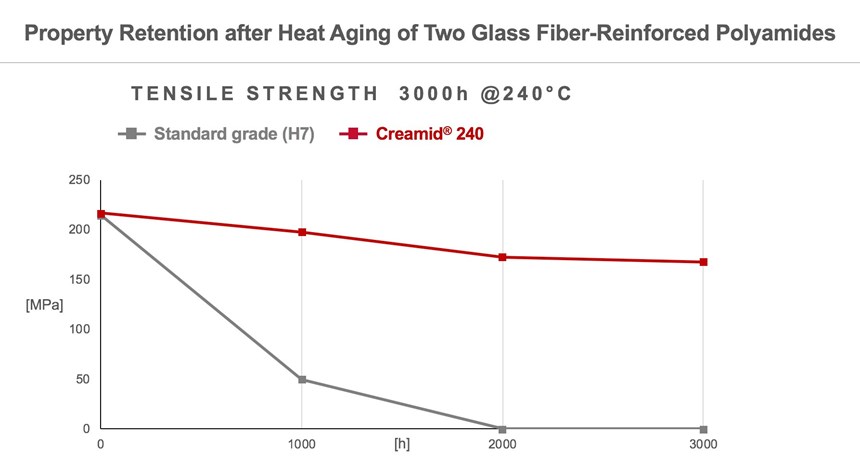

These compounds boast strength and stiffness of highly glass filled engineering polymers while maintaining high levels of critical mechanical properties even after continuous service at temperatures of 240 °C/464 F. Currently available grades, with glass fiber content of 35, 50, or 60%, exhibit dramatically improved property retention in comparison with similarly glass-filled standard nylon 66 compounds. At the same time they cost around 30% less per kilogram than high-performance polymers such as polyphthalamide (PPA) or nylon 4.6, while providing comparable performance.

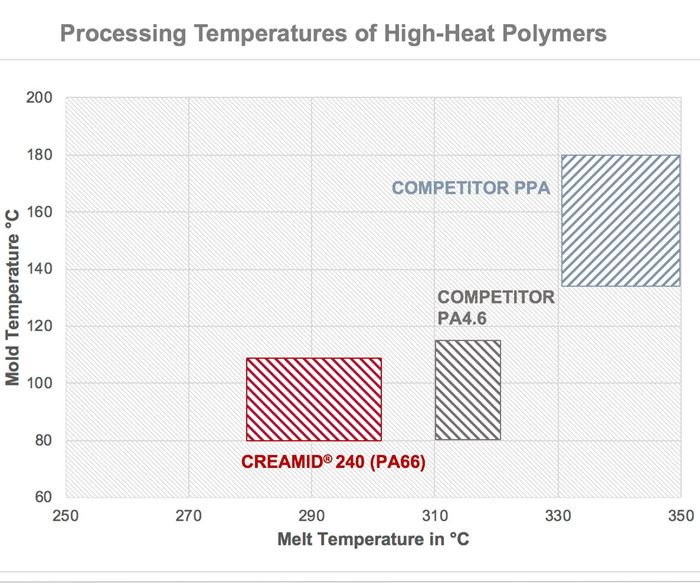

Said Dr. Hartmut Elsässer, global director of technology for engineering thermoplastics, “Additional cost savings with Creamid 240 H7.5 compounds are achievable in processing. These new materials exhibit lower melt and mold temperatures than competing nylon 66 compounds and high-performance products like PPA, providing economies in terms of energy consumption, cycle times, and tooling requirements.”

While the new compounds have processing temperatures in the range of 280 to 300 °C/536 to 572 F and mold temperatures of 80 to 110 °C/176 to 230 F, the corresponding ranges for PPA or nylon 4.6 are 330 to 350 °C/626 to 662 F and 130 to 150 °C/266 to 302 F. The company recommends Creamid 240 H7.5 compounds for automotive under-hood components such as charge air cooler end caps, air intake manifolds, quick-fit connectors, radiator end tanks, turbo air ducts and resonators, oil pump wheels, EGR valves, and thermostatic casings. Other possibilities include electronic connectors, diode carriers, and bobbins, as well as consumer products such as lamp sockets and connectors.

Related Content

-

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

-

Best Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

-

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.