Mold Simulation Now Optimizes Processing

Sigmasoft mold simulation now finds the optimum process conditions to suit the mold.

Simulation software provider Sigma Engineering (U.S. office in Schaumburg, Ill.) introduced at last fall’s Fakuma show in Germany a new tool said to “find out the optimum design and production conditions even before the mold is built.” New Sigmasoft Autonomous Optimization “finds automatically the best process setup to meet a specific demand,” according to the company. Part of new Sigmasoft release v5.2, Autonomous Optimization works with a new “virtual DOE (design of experiments) functionality. The molder can ask for a particular result and the software will automatically find the best production setup to meet this demand. For example, if a new job demands tight dimensional tolerances, it is possible to ask the software to minimize part deformation, and the virtual machine “will set up itself.” This eliminates the urgent pressure to identify the processing window for a new mold after it is built and delivered, without taking time to optimize factors such as energy consumption or cycle time.

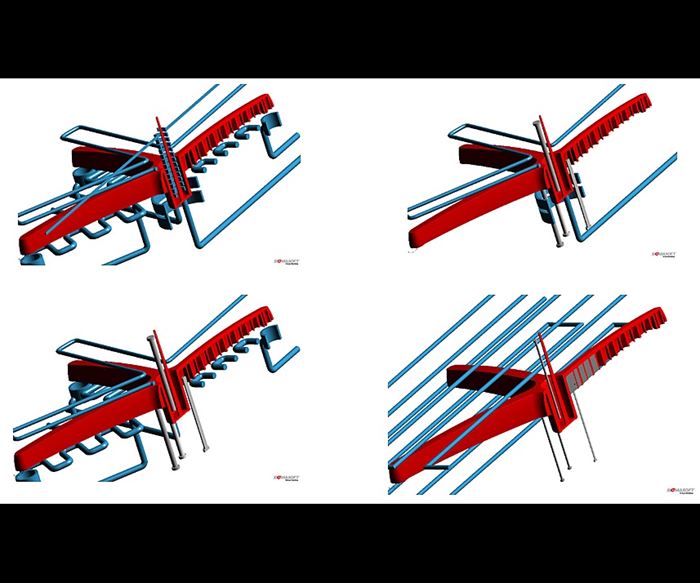

In the case of one early adopter of Autonomous Optimization, a thick-walled base for a rolling office chair had to be produced in a cycle time below 60 sec. The moldmaker identified the parameters he could vary in the mold to achieve the requested cycle time—mold material, layout and diameter of cooling channels, a conformal cooling concept, and high-conductivity pins. All the possible combinations of these variables gave a total of 40,000 different mold configurations. (Alternative cooling layouts evaluated by the software are pictured here.) The Autonomous Optimization simulation tool evaluated these possible scenarios to find the ones that produced a cycle time under 60 sec. Among those possible design combinations, it was then possible to filter the ones with lower cost. That eliminated conformal cooling in this case, while high-conductivity pins and water channels of a specified diameter were found to meet the objectives.

Related Content

-

How to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

-

How to Achieve Simulation Success, Part 2: Material Characterization

Depending on whether or not your chosen material is in the simulation database — and sometimes even if it is — analysts will have some important choices to make and factors to be aware of. Learn them here.

-

Injection Molding Simulation Meets the Real World

Direct data interface between molding simulation and the injection machine links the computer model to the real-world process. This can improve results from product and mold design through ongoing production. A case study demonstrates these benefits for automotive components in a family mold.