Thanks to This Material, There's No Hard Coating Needed

New additive that improves scratch/mar resistance in molded & extruded parts.

Here’s test data on a new additive that improves surface durability of engineering thermoplastics at very low loadings, and may even improve mechanical properties.

You want your new car’s gleaming interior to appear like new for as long as possible. After all, you paid handsomely for it. So you do your best to avoid knocks and gouges in daily use. So there’s no hiding your disappointment when, six months later, the interior panels, consoles, and gearstick cover, appear scuffed and old.

Designers of these nylon or polycarbonate products can’t rely on hardcoating or painting the exposed surface to avoid this marring. It’s simply too difficult and expensive. Automotive OEMs are not the only ones concerned with scratch and mar performance. Many molders and extruders of thermoplastics in consumer products, electronics, and interior furnishings also demand better performing resins that resist abuse and retain their surface quality as long as possible. Molders of such products are frustrated by the high rate of scuffing appearing on their nylon parts sometime between the injection molding machine and their end-use customer. Some have turned to a new and cost-effective approach.

TenasiTech (U.S. office in Marblehead, Mass.) has developed a new additive called Solid-TT that when compounded into resins—usually at only 1% by weight of the host polymer—provides significant improvements in scratch and mar resistance without the expense of painting or hard coating. Molded parts and extruded sheets made with this additive can withstand rougher handling without surface marring (see Starting Up, Jan. ’16). Here are further technical details and test data on this new technology.

SURFACE-TREATED CLAYS

Development of this additive began in the research laboratories of The University of Queensland in Australia. The research yielded patented organoclays with a new type of surface treatment. The unique organic treatment helps maximize the disassociation of the clays when compounded into thermoplastics.

The additive is not intended to replace hard coating. Companies that have already gone through the expense and time required to establish a hard-coating line are unlikely to change. But the vast majority of plastic products in any given resin market will never have the benefit of a high-performance coating or painting. Not only is hard coating too expensive for many end-uses, molded parts with curved surfaces are notoriously difficult to hard coat efficiently. Furthermore, extruded sheeting is commonly thermoformed, which involves stretching the sheet. This can mean that hard coating is not an option, given the potential for damage to the coating.

Solid-TT is a true polymer reinforcement, not simply a lubricant or other migrating additive. So there are no issues with surface rub-off or long-term durability. Products made with the new additive can withstand routine cleaning and maintain glossy surfaces.

The additive is compounded into resins using standard twin- screw extrusion. The resins can then be molded or extruded as normal. Molders say that cycle time is not increased, and only a slight increase in injection pressure is required.

Solid-TT additive has shown significantly improved protection against scratch or mar damage across a range of nylons of varying viscosity and also with acrylics. The additive does not degrade the polymers or cause significant discoloration. Importantly, impact and drop resistance is not impaired by the inclusion of the additive in thermoplastics. This has been a major drawback to previous attempts to create performance additives for surface hardness. The additive also does not affect the modulus of nylon 6.

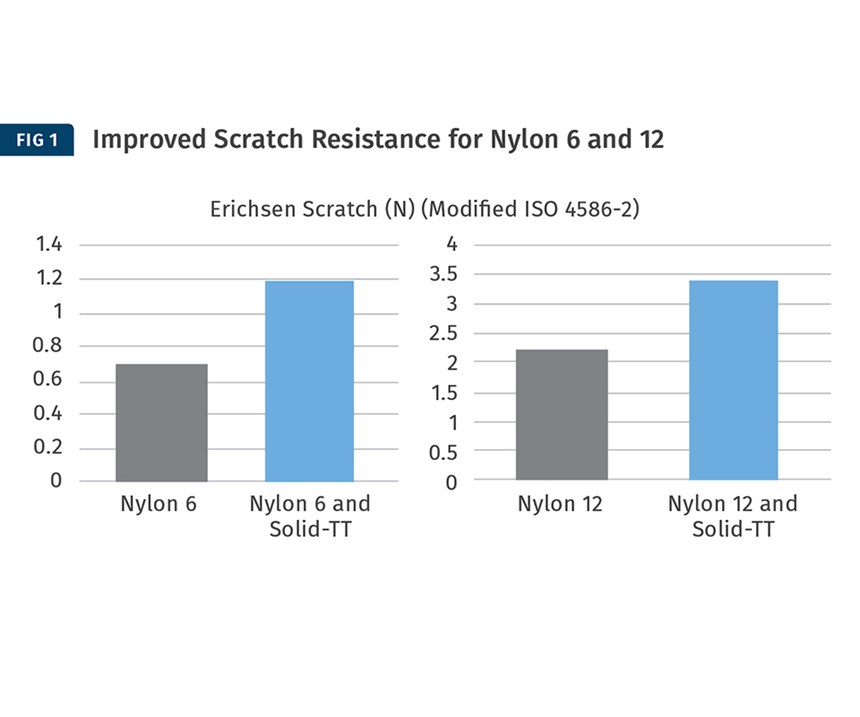

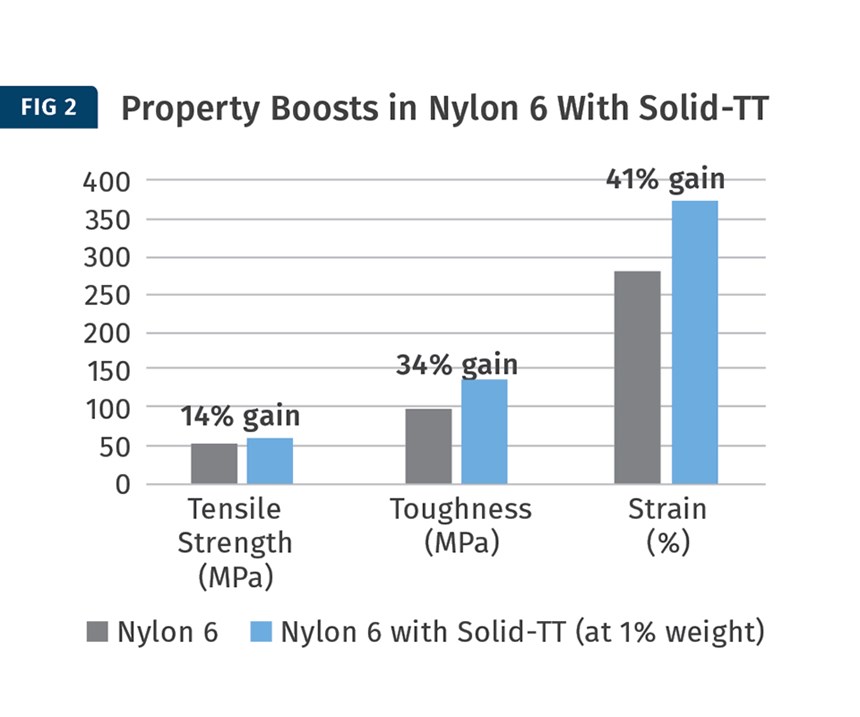

When Solid-TT was added to an extrusion- grade nylon 6, mechanical properties were significantly better than those of the same nylon without it. For example, there was a 41% gain in strain-at- break for Nycoa 1637 nylon 6 with 1% Solid-TT, compared with the nylon compounded without it. A 34% gain in toughness and 14% gain in tensile strength were also recorded (see Fig. 2).

Thermoplastics incorporating Solid-TT have undergone 1000 hr accelerated UV aging. The plastic did not show any additional deterioration when compared with the neat resin.

Furthermore, the additive maintained the excellent pencil-hardness performance after UV exposure. Chemical resistance of the plastic is also unaffected, which is logical, given the low addition rate of this performance additive.

SCRATCH & MAR TEST PERFORMANCE

Scratch and mar behavior can be incredibly complex, and there is no universally agreed-upon single test to measure performance. Among a wide array of tests, pencil hardness is a simple, shorthand method that can communicate across different polymers and is globally understood.

Other tests, such as Erichsen Scratch (ISO 4586-2) and Taber Linear Scratch (ISO 1518:2001) are commonly used for scratch testing. For mar resistance, friction and wiping tests such as Crockmaster are commonly used.

No method for guarding against scratch and mar damage will qualify according to every scratch test. This is true even for some hard-coating methods. The Solid-TT additive will not provide protection against more aggressive, gouging-type scratching. Tests such as Taber Abrasion can be very aggressive, and differentiating between polymers containing Solid-TT can be very difficult.

It is common that the ultimate scratch or mar qualification happens in the field. Processors or their OEM customers may have their standard lab test as well as a required period of time that the product must survive without excessive surface damage in normal use. Sometimes a field test is as simple as abuse with a pair of car keys, or a fingernail. In other cases customers subject their end product, such as a ski or a bottle, to a “use life” typical for its end market.

In tests, nylon 6 with Solid-TT improved scratch resistance by 71%, and transparent, cycloaliphatic nylon 12 with the additive exhibited improved scratch resistance of 55%, according to the turntable-type Erichsen Scratch Test (see Fig. 1). Mar resistance is different than scratch resistance. It is a change to the surface such as color, gloss, or haze caused by friction or rubbing, but without significant loss of material from the surface.

Rubbing tests are a good way to measure this: In so-called Crockmaster tests, a mechanical finger drags a standardized textile against the plastic surface, using a consistent force, for a predetermined number of cycles. To mimic normal use of an automobile interior this testing can require up to 40,000 cycles of cloth wiping. For mobile consumer devices, the number of cycles can be 5000 to 10,000 using a textile to match clothing. In either case, a visual assessment is made of the plastic with and without the additive.

Solid-TT has been shown to significantly reduce the marring when these tests have been performed on nylons and acrylics. Similar results are expected for polycarbonates and other polymers.

BEYOND NYLON

Scratch performance for polycarbonates with Solid-TT has shown pencil hardness of “H”, versus “2B” without the additive. This opens significant potential for PC molded products and sheeting where hard coating remains too expensive an option.

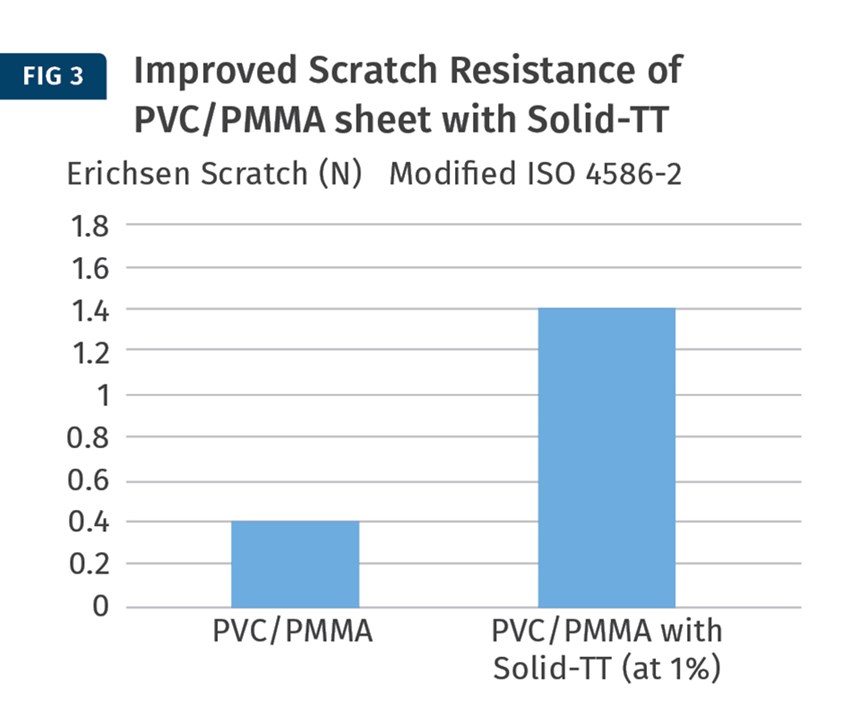

In external tests, PMMA formulated with Solid-TT showed damage at “7H” pencil hardness, vs. “4H” without the additive. What’s more, PET and PVC/PMMA alloys have shown very promising improvements in anti-scratch performance with the additive, though this work remains in development.

PVC/PMMA alloys are excellent options for sheeting in airplane interiors, such as bulkhead partitions. They are very tough and chemically resistant. But, like many polymers, they are subject to scratch damage. Hard coating of PVC/PMMA sheet isn’t an affordable option, and is unsuitable because the sheet will be thermoformed to the final product shape.

TenasiTech has measured the scratch resistance of the PVC/ PMMA alloy sheet and seen a tripling of the force required to leave a permanent scratch, as per the Erichsen Scratch test (Fig. 3).

ABOUT THE AUTHOR: Richard Marshall is CEO of TenasiTech Pty Ltd., headquartered in Australia. He has 22 years of experience with technology startups, venture funds, and top multinationals. He was coauthor of a book chapter on the commercialization of nanomaterials for industrial applications, published in 2013. He has an MBA from Oxford University, with Engineering and Science undergraduate degrees from the Queensland University of Technology. Contact: (518) 572-8572; richard@tenasitech.com, tenasitech.com.

Related Content

PFAS-Free Processing Aid for Blown Film Extrusion

Ampacet’s new processing aid said to perform as well as fluoro-based PPAs in blown film.

Read MoreCompatibilizers Aid Recycling & Upcycling of Mixed Resins

Compatibilizers are proving their worth in boosting critical properties such as impact/stiffness balance of PCR and PIR blends of polyolefins and other plastics.

Read More3 Types of 3D Printed Tooling for Injection Molding

3D printed tooling for injection molding, including mold inserts, components and end of arm tooling, were on display at the Plastics Technology Expo.

Read MoreGraphene-Enhanced Stretch Film Billed as 'World First'

Thinner, stronger films to be commercialized by Brazil’s Packseven in August.

Read MoreRead Next

Aussie Offers Nanoadditives For Mar/Scruff Resistance

surface-treated nanoclays protect acrylics, PC, PET, and other polar polymers.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read More