Non-Destructive, Non-Hazardous Approach to Rapid Internal Inspection of Molded Parts

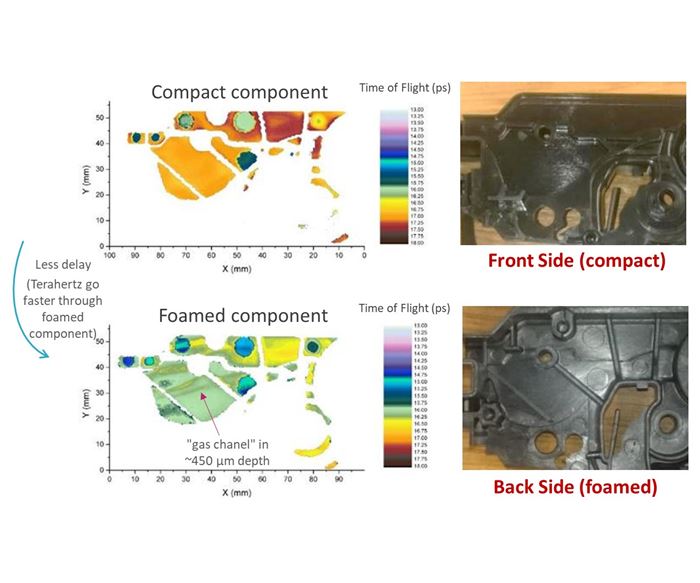

Terahertz spectroscopy allows in-line or off-line inspection of not only dimensions such as wall thickness, but also internal structure of solid or foamed parts.

What if you could perform dimensional QC and look inside plastic parts for voids, foreign bodies, foam structure, glass content and glass orientation in as little as 30 sec, non-destructively, using non-hazardous electromagnetic waves?

Sounds like a way to perform immediate shop-floor inspection and QC without sending parts to the lab? Well, that’s one purpose envisioned for the new TrexelVision system announced at last month’s Fakuma 2018 show in Germany. It allows you to “see the invisible” inside solid or foamed parts either in-line or off-line.

TrexelVision is the result of an exclusive distribution agreement that allows Trexel, the source of MuCell microcellular molding technology, to offer the STRIPP Control IM technology for injection molded parts from TeraTonics of France. STRIPP stands for Single Shot Terahertz Sensing for Rapid Industrial Product & Process Control. It employs the technique of terahertz (THz) spectroscopy, a method involving ultra-short pulses (measured in picoseconds, or 0.001 nanosecond) of electromagnetic radiation in the submillimeter wavelength range, in between microwaves and infrared light.

TrexelVision integrates a broadband source and detection system for the 0.1 to 1 THz spectral range, at which many polymer materials exhibit low-to-medium absorption. The system also includes an industrial control and data-acquisition unit with proprietary software for scan motion and data processing. It allows for robotic scanning of 3D objects based on their CAD files. It could potentially be located beside an injection press with the scan performed by the part-extraction robot.

STRIPP technology has already been used to measure the thickness of multilayer coatings, to inspect composites, and to measure glue layers in assemblies of composite parts. Analogous to infrared spectroscopy of multilayer plastic films, the TrexelVision system can operate in reflection or transmission mode. In reflection mode, the THz emitter and detector are mounted on the same head, allowing for one-sided access to the part.

For injection molding, it can perform wall-thickness measurements to ±3 microns. In foamed parts it could measure the thickness of the solid skin vs. the foamed core. It can also determine the density and uniformity of the foam cell structure; find voids or bubbles in solid parts; reveal foreign-body inclusions, internal weld lines, or the quantity and orientation of fiber reinforcements; and even show the boundaries between materials in multi-component parts. Another fascinating capability is to “slice” the part into virtual layers, revealing internal structure at different depths, similar to medical tomography (CT) scans.

CT scans, which use hazardous x-rays, are gaining popularity, despite equipment prices in the six-figure range. TrexelVision systems cost in the same order of magnitude but somewhat less than CT scanners, according to TeraTonics.

Related Content

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

Fast, Simple QC Method Directly Quantifies Recycled Content in Plastics

Novel fluorescence-based spin-out technology provides a rapid and reliable method to measure and certify recycled content in a wide range of plastics.

-

Dual-Mode Portable Thickness Gauge for Packaging

Hand-held “pen” measures sheets, containers, panels, large parts with magnetic or capacitance mode; controlled by Bluetooth phone app.