PEI-Based Resin with Surface Mount Technology (SMT) Capability

SABIC’s Ultem 3473 helps reduce weight of RF filters in 5G Macro cells by up to 40%.

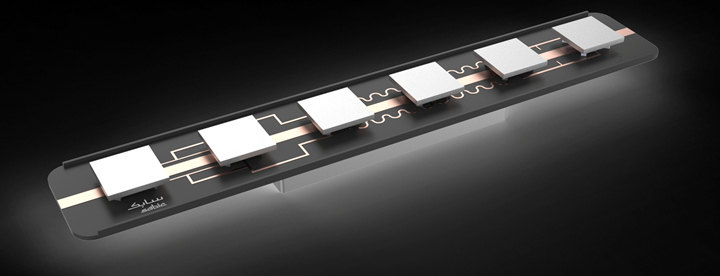

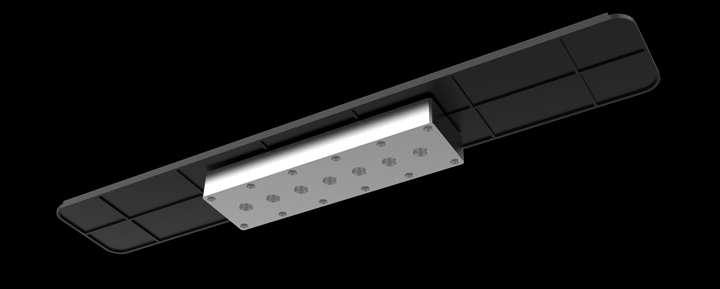

A new polyetherimide-based resin from SABIC is said to be the company’s first PEI with surface mount technology (SMT) capability. Ultem 3473 resin is said to address the growing trend toward smaller, lighter 5G macro cells by providing a possible replacement for metal. For example, Ultem 3473 resin can help reduce the weight of an aluminum radio frequency (RF) cavity filter by up to 40%. In a typical macro cell with 64 filters, this weight saving can be significant. Also, this resin reportedly can help facilitate the design of new, integrated antenna filter units (AFUs), which is not achievable with metal. Using injection molding, the dipole antenna matrix and RF cavity filter body can be produced as one piece. This approach simplifies production and may lead to additional weight savings and system cost reductions.

Ultem 3473 PEI boasts performance, processing and assembly advantages over die-cast metal and thermoplastics such as filled PPS. It is said to enable components to withstand very high temperatures, up to 500 F, during the assembly process. With a coefficient of thermal expansion (CTE) similar to that of metal, it has been shown to provide dimensional stability under a wide range of operational temperatures, from -40 F to 302 F, over the long term. Dimensional stability of the material, in turn, helps ensure consistent signal filtering of the RF cavity filter by minimizing dimensional variations over these temperature ranges. In contrast, the CTE of filled PPS products increases significantly at temperatures above 185 F to 194 F, according to SABIC internal testing.

Moreover, this resin reportedly provides excellent surface metallization performance during the chemical plating process. The result is good adhesion of the metal layer to the matrix, with low surface roughness. These factors help ensure low signal loss and long-term reliability. Customers that opt for new integrated AFU designs made with Ultem 3473 resin can significantly reduce cycle times compared to casting and machining aluminum. Injection molding multiple one-piece components can help manufacturers increase throughput, respond more rapidly to growing demand for 5G components and potentially reduce additional weight and system cost of 5G macro cells.

Related Content

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.

-

Melt Flow Rate Testing–Part 1

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number.

-

What's the Allowable Moisture Content in Nylons? It Depends: Part 2

Operating within guidelines from material suppliers can produce levels of polymer degradation. Get around it with better control over either the temperature of the melt or the barrel residence time.