Platform Collects, Transmits and Saves Flow Rate and Temperature Data

Scientific injection molding adherents can use temperature and flow rate data to confirm cooling water condition requirements; new flow regulator automatically adjusts flow rate.

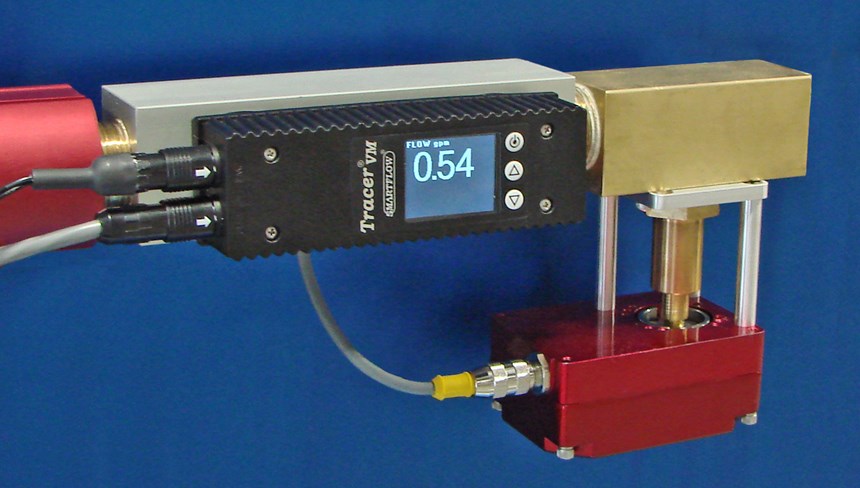

Burger & Brown Engineering Inc.’s TracerVM electronics platform gathers and shares flow rate and temperature data from up to eight TracerVM Base flowmeters installed in injection mold cooling circuits. TracerVM Base Flowmeters purchased separately can be connected via cable to the TracerVM Bluetooth Interface.

The interface wirelessly transmits data to display on a mobile device up to 20 meters away, and the mobile app can display data from up to 30 units at one time, creating flow condition data log files. These can then be saved onto USB flash drive to document a process’s mold cooling water conditions.

TracerVM can also communicate over an Ethernet connection with a local network. Data Logger PC software, which is included with the interface, displays and stores temperature and flow rate data. In addition to saving comma-delimited data files that can be placed into a spreadsheet for reference or analysis, the software enables customizable visual alerts for low- or high-temperature and flow-rate limits.

The TracerVM Bluetooth Interface housing is a NEMA 4X compliant gasketed, water-resistant, plastic enclosure designed to protect internal circuitry from occasional water spray. Ethernet and USB ports are located on the housing, and the USB port may be used to charge mobile devices or connect USB flash drives for temporary data storage. Operating temperature ranges from 0 to 52 C (32 to 125 F). The unit requires and 8 to 28V DC external power supply with Earth Ground, and cord grips are included to maintain water resistance.

By installing economical non-display flowmeters in the cooling water line vs. flowmeters that include individual displays, processors can save money with the TracerVM Bluetooth Interface, according to Burger & Brown. In addition, proponents of scientific injection molding can use temperature and flow rate data from TracerVM Base units to confirm cooling water condition requirements and efficiency, while optimizing cycle times. Medical molders may also use this data to validate quality or regulatory process requirements.

New Automatic Flow Regulator

The TracerVMA with AutoReg is a new automatic flow regulator that automatically adjusts flow rate to the required user-selected volume regardless of changes in line pressure. This results in a more consistent flow rate with more control over cooling water conditions in critical molding situations. The electronics control communicates with the valve actuator which adjusts the valve opening to maintain the correct flow rate. Local or remotely mounted electronics control allows for convenient positioning. Electronics control may be mounted up to 2.9 meters (9.5-ft) away from the flow sensor and regulator.

At the show, Milacron and Sumitomo will have new TracerVM products installed and operational on injection molding machines at the show, and RJG will have examples of the Smartflow products working with its data acquisition systems.

Related Content

-

Machine-Side and Central Chiller Lines, Industry 4.0 Controls to Launch

Frigel will use K 2022 to showcase a number of developments in process cooling, including new and expanded lines of central and machine-side chillers, as well as advanced control platforms.

-

Is Your Water System Setup Helping or Hurting Your Molding Plant Productivity?

The plant water system is a critical component of an injection molding facility. A poorly designed or maintained water-cooling system can have a serious impact on production efficiency and cause many maintenance issues. Here’s what you need to know — and ask — to prevent those problems.

-

Multicoupling Range Extended

Hasco‘s quick-connect system for multiple cooling circuits has added U.S., French and HT versions.