Tech Center Boasts Five Engel Machines and MuCell Technology

A new Detroit-area tech center gives automotive OEMs and their tier suppliers a production-scale lab to test the very latest molding technologies.

On June 29, in conjunction with its first ever Automotive Trend.Scaut event in North America, Austrian injection molding machine and automation supplier, Engel (North American headquarters in York, Penn.) helped inaugurate a new tech center in Livonia. Engel partnered with SA Engineering on the facility, which is fully owned by SA’s parent, SA Automotive.

The operation—which has 42,000-ft2 of floorspace, eight independent offices, and a large conference room—was overhauled to accommodate SA and its technical partners. The second floor of the building is being converted into a traveler’s office area for the SA Automotive team, according to SA spokesperson Lydia Araya.

Engel has installed five injection molding machines at the center, including a duo 3500-ton press with an easix six-axis articulating arm robot; a duo 1650-ton wide platen machine with integrated viper 60 robot; a duo 1000-ton wide platen machine with an integrated viper 40 robot; a duo 660-ton press with a viper 20 robot; and a 285-ton tiebarless victory machine, equipped with Engel’s watermelt technology. All the machines are capable of running Trexel’s MuCell process, and the 3500-, 1650-, and 1000-ton duo’s are also equipped with Engel’s coining technology.

In addition to Engel, SA Engineering has brought on other technical partners into the tech center, including Trexel, which is offering its MuCell microcellular foam technology on site (read more here), and moldmakers Excel RP Inc. and Excel Global LLC, which will assist with mold creation and molding for R&D, prototype and low-volume production.

SA spokesperson Lydia Araya told Plastics Technology that other companies have asked to co-locate at the Livonia site, but to date none has been approved. The center currently has eight full-time employees, with two part-time workers and another two full-time consultants on site. Araya said SA is continuing to hire and once staffing is complete, the center will have 13 full-time employees.

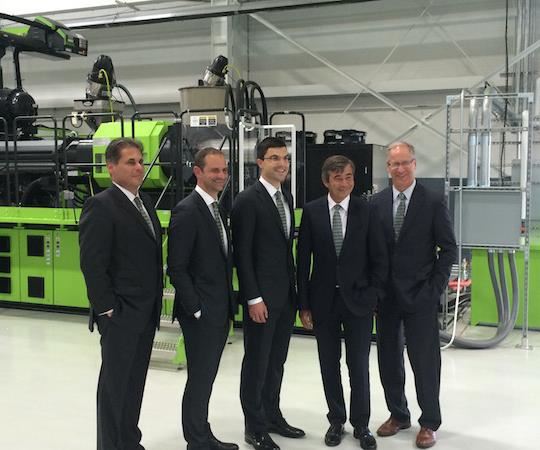

The import of the event and the new center was made clear by the number of Engel executives who turned out, including the company’s global and North American leadership teams. Current chairman, Peter Neumann, was joined by his successor, Stefan Engleder, who will take over the company in November, as well as CSO Christoph Steger, Engel North America President Mark Sankovitch, and Wolfgang Degwerth, VP of sales and customer service for Engel North America.

At the Trend.Scaut event that preceded the tech center opening, Neumann noted that automotive is Engel’s strongest segment globally, accounting for half of the company’s turnover, which came in at $1.38 billion for fiscal year 2015. “Engel focuses much of our R&D on this segment,” Neumann said. “For the last few years, North America has been a very, very active market, especially on the technology side.”

Neumann said this new tech center fits with the company’s efforts at application engineering and system solutions, with U.S. R&D and process development capabilities also located in York, Penn., and Corona, Calif. In addition to SA Engineering, Engel will soon have four machines for process and application development at Hi-Tech Mold & Engineering Inc., Rochester Hills, Mich. At this time, Hi-Tech has a 3500-ton duo with coining technology and a 1000-ton wide platen duo, with both machines featuring full robotics. This year, it will add a 340-ton press, as well as a 660-ton wide platen machine.

SA Engineering is fully owned by SA Automotive, which has two plants in the Detroit area and one facility in Mexico. SA Automotive is owned by AESSE Investments, a private holding company, which also owns SACO AEI Polymers with locations in Europe, North America, South East Asia, China and India.

Related Content

Structural Foam Injection Molding Line Extended

At K 2022, Wilmington Machinery introduced the dual-injection Lumina MP1200 medium pressure molding machine.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreInternal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

Read MoreRead Next

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so that the barrel appears to be turning clockwise around a stationary screw.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More

.png;maxWidth=300;quality=90)