Tooling: Off-the-Shelf Conformal Cooling via Standardized Components

Ready-to-order conformally cooled cold-sprue and hot-drop bushings from Milacron’s DME business allow molders to reap the benefits of 3D printed cooling channels in key areas of the tool without the cost of one-off custom analysis, design and fabrication.

For the past two years, DME, a Milacron brand, has offered custom core and cavity inserts with TruCool conformal cooling, made by the direct metal laser melting (DMLM) 3D printing process. Recently, DME launched standard mold components incorporating conformal cooling technology. DME is starting with standard hot and cold sprue bushings.

David Moore, business development manager for DME, tells Plastics Technology that standardized components with conformal cooling can provide big benefits and lower upfront costs thanks to bulk production. “You don’t have to go through that analysis process; you don’t have to go through a design and trial phase,” Moore says. “It gives molders the freedom to add conformal cooling as a standard component instead of a custom-designed solution.”

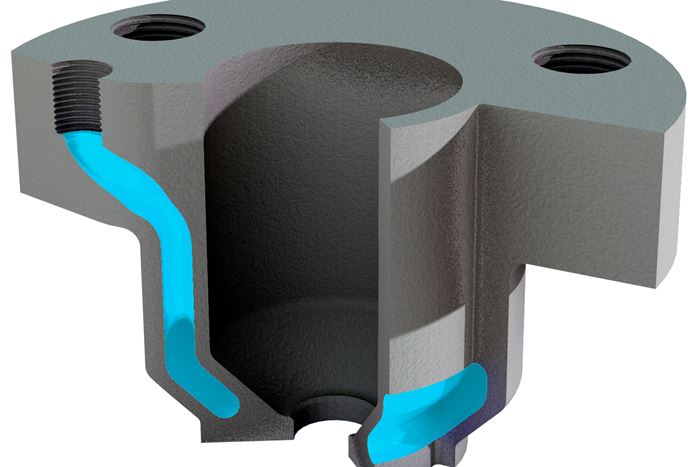

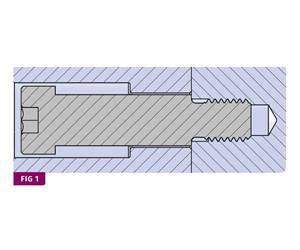

DME’s entire B Series of cold sprue bushings with 1-in.-diam. shank will be available with conformal cooling. The components still feature the same external geometry, sprue taper and diameter, allowing them to act as a drop-in replacements for their conventional counterparts. The only difference is the addition of two ports for cooling inlet and the outlet. “They’re pretty much plug and play,” Moore says. “You can pull an old one out and put a new one in.” Molders or moldmakers would need to mill a channel in the back of the cavity block to accommodate the bushing’s water circuit. The bushings are currently printed from MS1 maraging steel, with a stainless version coming soon, and DME is also outfitting its A Series of cold sprue bushings, which have a ¾-in. shank, with conformal cooling channels.

For parts where the sprue’s diameter is the thickest section of the component, conformal cooling at the bushing could reduce cycle times that have been extended to compensate for the sprue. Stringing arising from ejecting too soon can also be eliminated, DME says. And since the sprue can be cooled more quickly, if a tool could benefit from a larger sprue—decreasing the amount of pressure needed to fill the mold—it could be used without impacting the process. Decreasing the amount injection pressure required might enable a mold to be run in a smaller press, Moore notes.

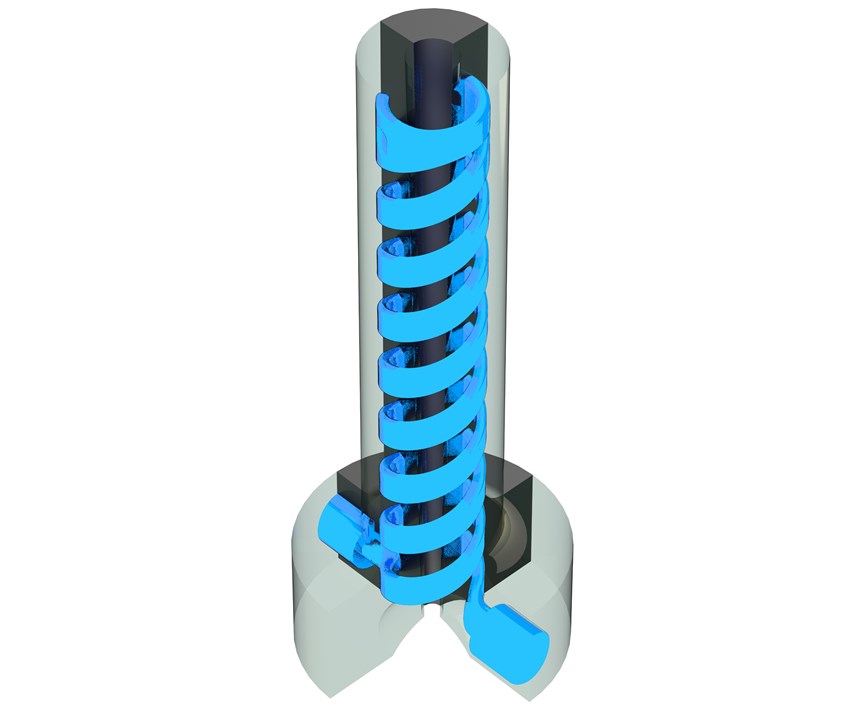

DME is also introducing bushings for hot drops and valve gating that will surround a nozzle tip with conformal cooling for greater control. Bringing cooling very close to the tip for greater control of valve-gate timing and solidification at the nozzle reportedly can help prevent gate blush and splay, as well as stringing. Made from H13 steel, the bushings have a few different options for face design and water-channel connections. The bushing can protrude through for maximum cooling, which would leave a witness mark; or a portion of the face can be milled off entirely so that the bushing is completely recessed.

To accommodate different drop-bore diameters, the center hole is smaller, allowing a molder to machine that opening to match the existing system. “This would work for a variety of different diameters and gating scenarios,” Moore says.

There are two versions of the hot-drop bushing: one shallow and one with a deeper draw. Moore says the versatility of the center bore diameter means it can be milled once it’s inserted in the tool to match the customer’s drop configuration is. Up next for the hot bushing line will be a larger diameter version. DME is also working on other conformally cooled standard components, including core pins.

Related Content

How to Optimize Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Applying a scientific method to what is typically a trial-and-error process. Part 2 of 2.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 2)

Follow these tips and tricks for a better design.

Read MoreHow to Mount an Injection Mold

Five industry pros with more than 200 years of combined molding experience provide step-by-step best practices on mounting a mold in a horizontal injection molding machine.

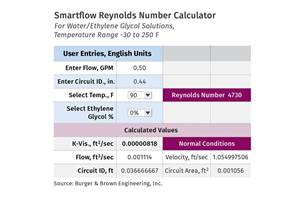

Read MoreCooling Geometry and the Reynolds Calculation

The original Turbulent Flow Rate Calculator worked well with a round circuit diameter, such as a drilled passage, but not as well using hydraulic diameters. Here’s how the problem was fixed.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read More