US Extruders Debuts With New Machines, Novel Features

Machine builder that started up last August offering a variety of innovative designs.

At its first-ever NPE, US Extruders is showing a new generation of highly engineered, custom single-screw extruders, displaying a 2.5-in. 24:1 L/D; a 3.5-in. 24:1 L/D extruder; and a compact custom medical extruder.

The firm’s 2.5-in. and 3.5-in. extruders will include the following features:

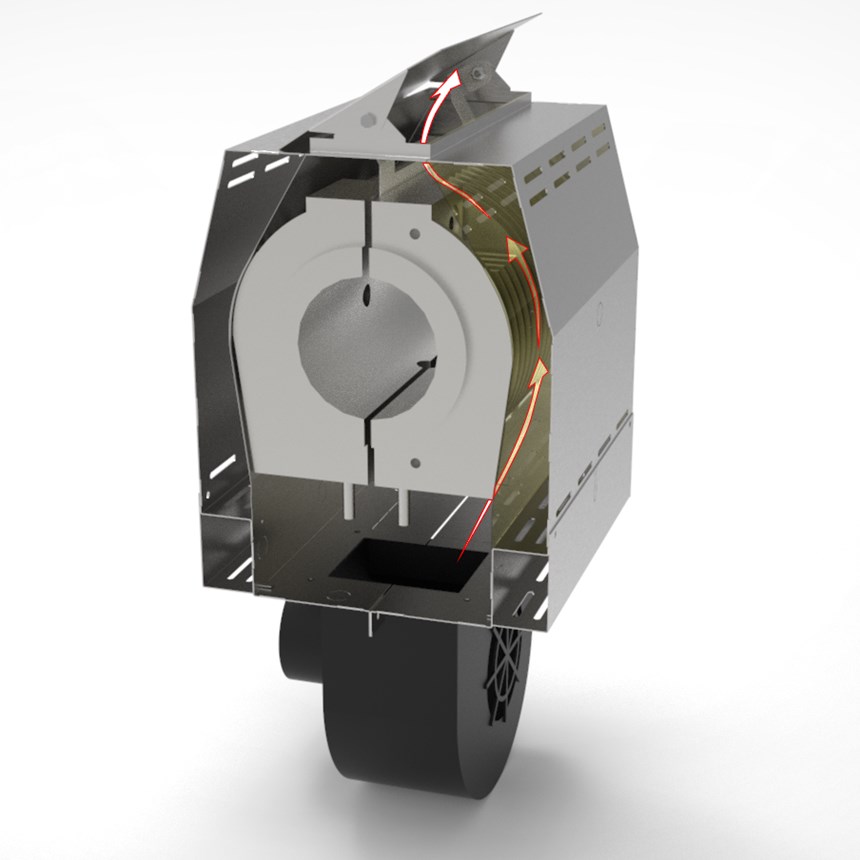

- Unique heater shroud design made up of individual stainless steel shrouds that provide quick and easy access to each zone. The dual-layer stainless steel provides a relatively cool-to-the-touch outer layer. Thermocouples go through the side for easy replacement. Each shroud includes an adjustable exhaust deflector. Integral wireways are also built into the design to provide a clean look and easy access to wires.

- C-clamp with an easy open, over center lever with thumb release safety lock. Lever action swing bolt needs no wrench adjustment once the position is set. Durable aluminum heaters allow for consistent heating throughout clamp. Linkage counterbalances the two halves so they open together.

- Motor mounted on a pivoting base. This unique design provides auto-adjusting tension on the V-belts. The motor mount’s pivot location is determined by the motor weight and torque reaction to always provide the correct tension.

- Feed throat that is integral to the barrel with an air/water cooled jacketed feed area. The one-piece feed eliminates alignment and step/mating issues that can be found in conventional cast iron feed section with bolt-on barrels. The standard bi-metallic feed area provides maximum wear resistance.

- ProControl controls by ProSystems Integration, which will be in the same booth. The 2.5 inch will be equipped with ProControl Deluxe. This is a comprehensive HMI system to control the entire extrusion process. It improves production efficiency and quality with recipe management, data acquisition, reporting, and alarm analytics. The 3.5 inch will be equipped with ProControl DCR. This is a cost-effective HMI alternative to discrete controls. It includes basic extruder control along with recipe and alarm enhancements.

The compact custom medical extruder includes a servo drive, swappable barrels, washdown design, integrated control cabinet with unique die wiring management, and many more features designed for the medical and pharmaceutical industries. The machine has swappable barrels in 0.50-, 0.75, and 1-in. sizes. This machine also has the medical version of ProControl touchscreen control system.

Related Content

-

Zeus Expands Catheter Capacity, Adds Minnesota Plant

State-of-the-art facility said to open this summer.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Is Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.