2900 S 160th St.

New Berlin, WI 53151 US

800-423-3183 | 262-641-8600

aecplastics.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

AEC Supplies the Following Products

- Bag and Drum Dumpers

- Blenders (non-intensive)

- Box Tilters

- Chillers

- Conveying Equipment (pneumatic and Mechanical)

- Desiccant for Dryers

- Dryers for Resins

- Granulators

- Heat Exchangers

- Heat-transfer Fluids

- Hopper Loaders

- Knives for Granulators, Pelletizers

- Shredders, Guillotines

- Temperature Controllers, Monitors

Trade Names Offered by AEC

- Whitlock

- Application Engineering

- Hydreclaim

- Nelmor

Editorial, News, and Products

-

AEC Extends Warranty on BD Series Blender

Coverage extended from previous term of one year.

-

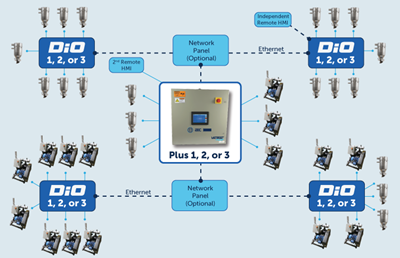

Conveyor Controller Ideal for Expanding Plants

Billed as the most flexible and reliable discrete wired conveying controller on the market.

-

Wheel Dryers for Beside-the-Press, Small Central Applications

Precision control on the dryer series reportedly prevents the thermal, chemical and physical material degradation that can result from long drying times at high temperatures and high air flow.

-

Wisconsin Firms Unite in Battle Against Covid

Teel Plastics opened new plant in record time, partnering with AEC & Aqua Poly Equipment Co. to expand production of swab sticks to fight pandemic.

-

ACS Adds Midwest Regional Sales Manager

Auxiliary equipment supplier names Mike Tuchalski to post.

-

Make Your Auxiliaries More Energy Efficient

Don’t overlook your auxiliaries when you’re looking for areas to cut energy consumption. Implementing simple changes won’t break the bank and could pay off big by improving your bottom line and reduce your carbon footprint.

-

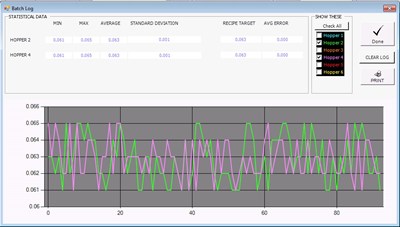

Blending: 'Smart' Software Saves Labor Costs, Boosts Quality

Helps operators make blending decisions and reduce errors when manually adjusting recipes.

-

Follow These Steps to More Efficient Central Pneumatic Conveying

Depending on when you bought and installed it, there are ways to tweak your central pneumatic conveying system to improve its performance and save you some money.

-

NPE2018 Auxiliaries: A Path to Industry 4.0 Emerges

Industry 4.0 dominated the news in auxiliary equipment at the show, but many questions remain for both suppliers and processors.

-

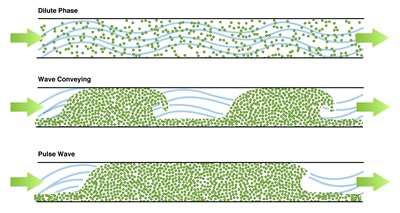

NPE2018 New Technology Focus: Resin Conveying

From RFID couplings to 'Wave' conveying, material is moving smarter at NPE.

-

ACS Group Positions Itself as a One-Stop Shop for Plastics Auxiliaries

The AEC, Sterling and Cumberland brands bring new products and a deep well of experience to NPE2018.

-

NPE2018 New Technology Focus: Process Cooling

Key themes in chillers at NPE2018 are efficiency, connectivity and transparency.

-

Auxiliaries at NPE2018: Packing More Functions in Less Space

Auxiliary equipment suppliers are building more and more technology into their products, packing more physical and virtual functions into the same or smaller footprints.

-

ACS Group Opens New Technology Center

Less than a half mile from its primary manufacturing operations, auxiliary equipment supplier ACS Group has opened a new technology center in New Berlin, Wisc.

-

‘New Normal’ Marks 30th Chinaplas Show

Show breaks attendance records as Chinese economy slows.

-

'Talking’ Machines Pave the Way for Processing Plants of Tomorrow

At the convergence of smarter equipment, open communication protocols, and more powerful networks, a new shop floor emerges where groups of intelligent machines work seamlessly as integrated systems.

-

Auxiliaries: A New Frontier in Metal Replacement

Stainless steel has been the de facto material choice for machine components like tanks and hoppers for forever, but do rotomolded plastics make more sense?

-

AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

-

Tec Air Moves Molding From Illinois to Indiana

Tec Air, a designer and molder of air movement components, is shifting its operations from Illinois to Indiana in a move that will more than double its space.

-

On Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

-

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

-

K 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

-

NPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

-

Heating & Cooling at NPE 2003

Smaller, more efficient, and environmentally friendly are the themes for new heating/cooling products at NPE.

-

Six Things You Should Know About New Eco-Friendly Chillers

If you never paid much attention to what kind of refrigerant is circulating inside your plastics chillers, it may be time you did.

-

Process Cooling Goes for Performance Plus Affordability

At the NPE 2009 show in Chicago, half a dozen exhibitors showed new cooling equipment that emphasized improved performance at about the same or lower cost.

-

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

-

NPE 2006 News Wrap-Up: Fluid Temperature Control: Saving on Energy and Maintenance

At NPE in Chicago, chillers and TCUs were put on a lean energy diet and redesigned for greater durability. Suppliers also added features while taking out cost.

-

NPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

-

NPE 2006 News Wrap-Up: Brains and Brawn - New Robots Are Handier Than Ever

Injection molding robots introduced at NPE pushed the work envelope for speed, reach, payload capacity, ease of programming, and ability to handle more sophisticated tasks.

-

Learning to Master In-Mold Labeling

As in-mold labeling, or IML, attracts a growing following among U.S. molders, some are finding that mastering a complex new technology is no small task.

-

What to See at NPE 2006: Heating and Cooling

Most of the news at the show is in fluid-circulating mold-temperature-control systems.

-

What to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

-

Magnetic Separation Simplifies Multi-Material Scrap Recovery

Recent trends to-ward multi-material molding, hard/soft overmolding, and dual-durometer coextrusion create growing volumes of scrap that is difficult or impossible to reuse.

-

Molder Saves Energy and Maintenance Headaches With New Type of Quiet-Running Chiller

The first plastics molder to use a radically new kind of chiller was looking for improved reliability to keep its plant running 24/7.

-

Resin Dryers: Which Type Is Right for You?

Processors today face bewildering choices of at least five basic types of dryers, whose capabilities are subject to conflicting claims from equipment suppliers. For the buyer, the most basic questions are: How much drying is needed for the job and which dryer types are up to the task?

-

Six-Axis Robots: Where They Fit in Injection Molding

Injection molded parts are typically demolded with simple pick-and-place automation—a top-mounted, gantry-style (also called Cartesian, linear, or traversing) three-axis robot.

-

Solving Gravimetric Blender Problems

Gravimetric blenders offer plastics processors considerable savings.

-

New Granulators Galore at NPE

Processors with scrap to grind must have noticed the prominence of screenless granulators with distinctive hooked “S-rotor” blades at the NPE show in Chicago.

-

NPE News Wrap-up - Water & Oil Temperature Control

If you’re the sort of manager that can’t resist checking up on your plant after you go home for the night, now you can click on your web browser and read out mold temperatures right there on your PC.

-

NPE News Wrap-Up: Materials Handling

The big show in Chicago presented more new loaders, feeders, blenders, and conveying controls than you could count. They’re more flexible, easier to maintain, and easier to control. Many are web-enabled, and some are lower in cost.

-

NPE News Wrap-up: Robots

From micro to maxi, from simple sprue pickers to sophisticated six-axis models, NPE had it all. A raft of new robots, faster and smarter than ever, will help make automation an irresistible choice for U.S. molders.

-

Greater Pickings in Robots for Injection Molders

The newest crop of robot automation for injection molding machines, displayed recently at the Platex show in Osaka, Japan, and the Plast-Ex Show in Mississauga, Ont., continue the trend toward six-axis jointed-arm models and improved servo-driven, beam-mounted units seen at last year's NPE show in Chicago. The latest introductions also include new controls for servo-driven robots, new units designed to work in palletizing cells, and a range of new sprue pickers in servo and pneumatic models.